V-shaklidagi quruq sovutish tizimlarini tushunish va optimallashtirish

Ushbu keng qamrovli qo'llanma o'rganadi V shaklidagi quruq sovutish tizimlar, ularning dizayni, afzalliklari, qo'llanilishi va optimal ishlashi uchun mulohazalar haqida batafsil ma'lumot. Biz texnik jihatlarni ko'rib chiqamiz, ularni boshqa sovutish usullari bilan solishtiramiz va muvaffaqiyatli amalga oshirish uchun asosiy omillarni ta'kidlaymiz. Muayyan ehtiyojlaringiz uchun to'g'ri tizimni qanday tanlash va uning samaradorligini oshirishni o'rganing.

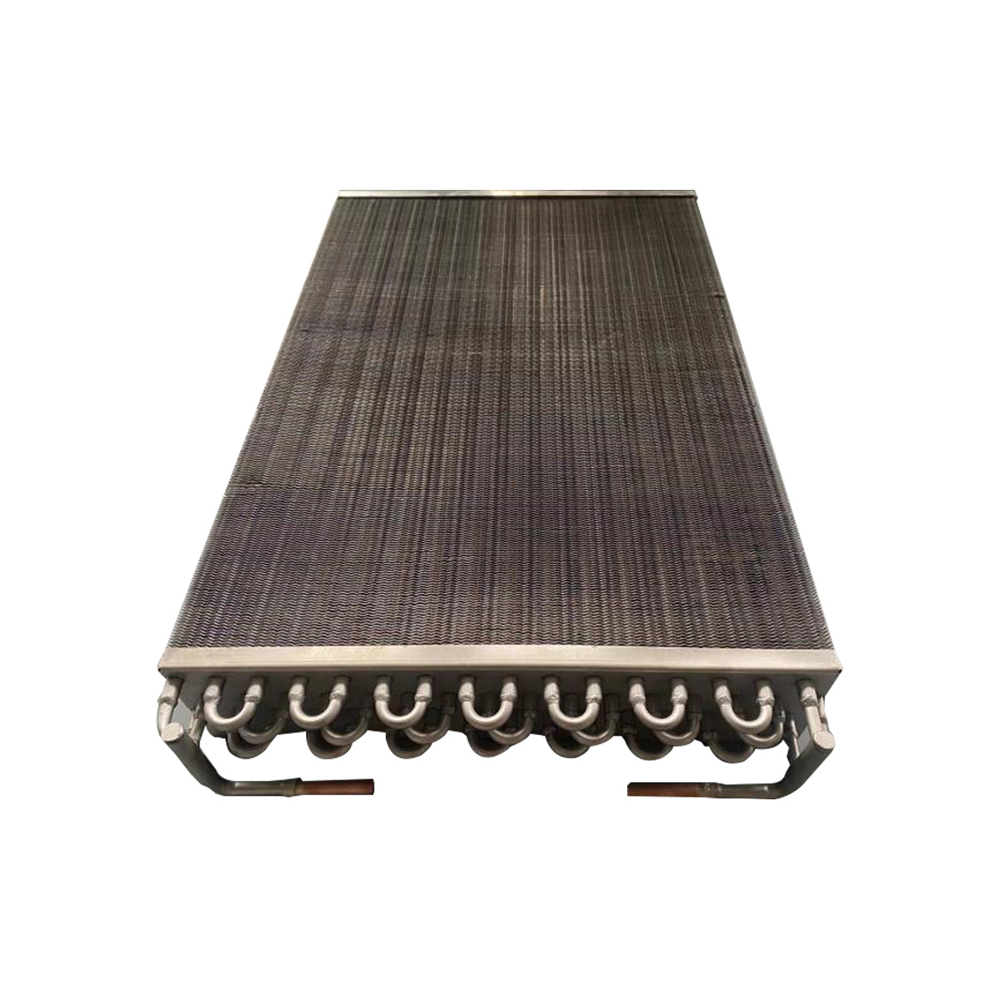

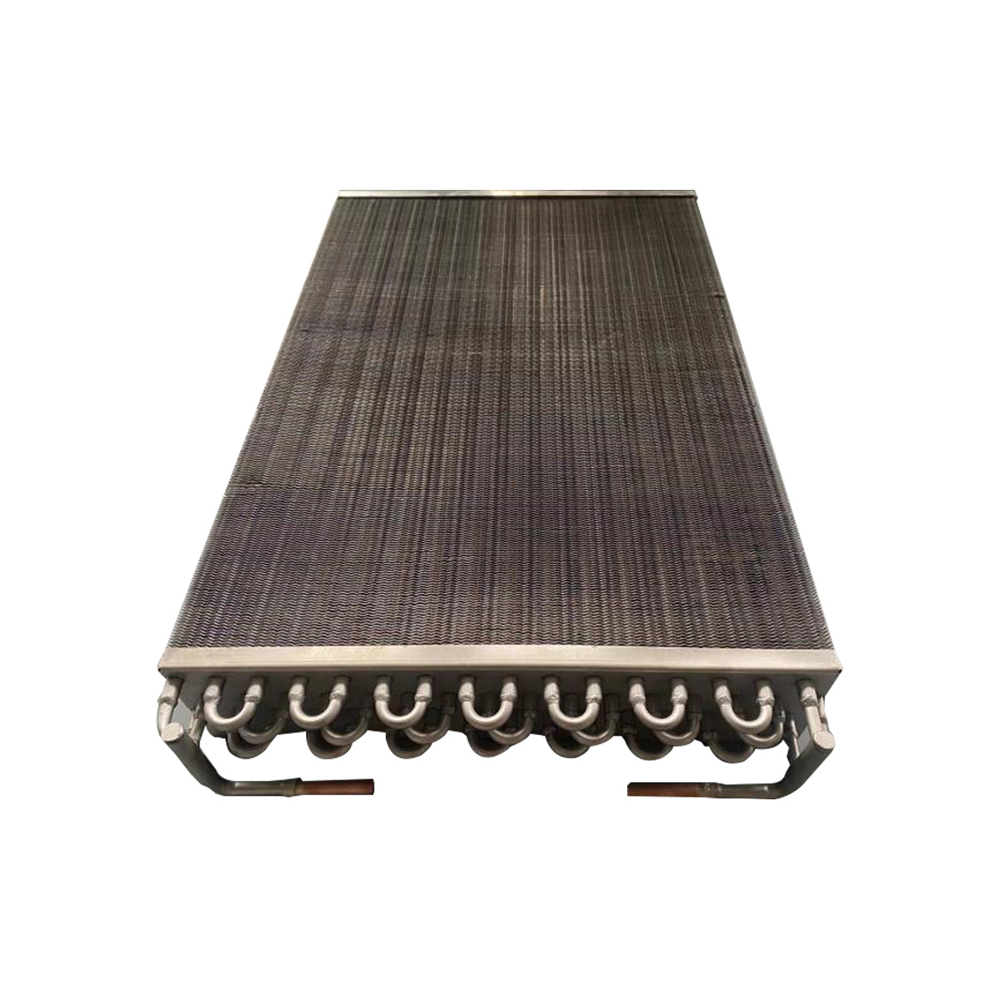

V-shaklidagi quruq sovutish nima?

V shaklidagi quruq sovutish elektr energiyasini ishlab chiqarish va sanoat jarayonlarida keng qo'llaniladigan havo bilan sovutilgan issiqlik almashinuvi tizimining bir turi. Suv bug'lanishidan foydalanadigan nam sovutish minoralaridan farqli o'laroq, V shaklidagi quruq sovutish tizimlar issiqlikni tarqatish uchun faqat havoga tayanadi. V-shakli havo oqimi va issiqlik uzatishni optimallashtirish uchun V shaklida joylashtirilgan qanotli quvurlar konfiguratsiyasini anglatadi. Ushbu dizayn samaradorlikni oshiradi va boshqa quruq sovutish konfiguratsiyalariga nisbatan umumiy joyni kamaytiradi.

V-shaklidagi quruq sovutish tizimlarining afzalliklari

V shaklidagi quruq sovutish bir nechta asosiy afzalliklarni taklif qiladi:

Suv iste'molini kamaytirish

Nam sovutish tizimlaridan farqli o'laroq, V shaklidagi quruq sovutish suvdan sezilarli darajada foydalanish zaruriyatini yo‘qotib, uni barqaror va ekologik toza variantga aylantiradi, ayniqsa, suv tanqis bo‘lgan hududlarda. Bu an'anaviy evaporativ sovutish usullari bilan solishtirganda sezilarli foyda.

Pastroq operatsion xarajatlar

Dastlabki sarmoya nam sovutishdan yuqori bo'lishi mumkin bo'lsa-da, suv va kimyoviy tozalash xarajatlarining kamayishi uzoq muddatli operatsion xarajatlarni kamaytirishga olib kelishi mumkin. Bu tizimning ishlash muddati davomida sezilarli darajada tejashga olib kelishi mumkin. ning samaradorligi V shaklida dizayn bu xarajatlarni tejashga hissa qo'shadi.

Ekologik manfaatlar

Suv sarfini minimallashtirish va suv bug'lari va kimyoviy moddalarning atmosferaga chiqishini bartaraf etish orqali; V shaklidagi quruq sovutish uning atrof-muhitga ta'sirini sezilarli darajada kamaytiradi. Bu yanada barqaror energiya yechimiga hissa qo'shadi.

Ishonchli ishlash

V shaklidagi quruq sovutish tizimlar odatda mustahkam va ishonchli bo'lib, nam sovutish minoralariga qaraganda kamroq texnik xizmat ko'rsatishni talab qiladi. Ularning dizayni ifloslanish va korroziyani kamaytiradi, bu esa ishlash muddatini uzaytiradi.

V-shaklini boshqa quruq sovutish tizimlari bilan solishtirish

Boshqa quruq sovutish usullari mavjud bo'lsa-da, V shaklida dizayn alohida afzalliklarga ega. Keling, uni boshqa umumiy konfiguratsiyalar bilan taqqoslaylik:

| Xususiyat | V-shakli | Boshqa quruq sovutish turlari (masalan, A-ramka) |

| Havo oqimining samaradorligi | Yuqori, optimallashtirilgan V shaklidagi dizayn tufayli | Odatda V shaklidan pastroq |

| Iz | Boshqa dizaynlarga qaraganda kichikroq | Kattaroq bo'lishi mumkin |

| Xizmat | Nisbatan kam texnik xizmat ko'rsatish | Ta'mirlash ehtiyojlari har xil bo'lishi mumkin |

V-shaklidagi quruq sovutishning qo'llanilishi

V shaklidagi quruq sovutish turli sohalarda ilovalarni topadi, jumladan:

- Energiya ishlab chiqarish: Elektr stansiyalarida, ayniqsa suv resurslari cheklangan hududlarda sovutish kondensatorlari.

- Sanoat jarayonlari: neftni qayta ishlash zavodlarida, kimyo zavodlarida va boshqa sanoat sharoitlarida sovutish texnologik suyuqliklari.

- Markaziy isitish va sovutish: tuman energiya tizimlarini samarali sovutishni ta'minlash.

V-shaklidagi quruq sovutishni amalga oshirish bo'yicha fikrlar

Muvaffaqiyatli amalga oshirish a V shaklidagi quruq sovutish tizim bir qancha omillarni, jumladan, ob-havo sharoiti, issiqlik yuki va mavjud bo'sh joyni diqqat bilan ko'rib chiqishni talab qiladi. Loyihani boshlashdan oldin puxta texnik-iqtisodiy asoslash juda muhimdir. Mutaxassis ko'rsatmalari va yuqori sifat uchun V shaklidagi quruq sovutish yechimlar, murojaat qilishni o'ylab ko'ring Shanxay SHENGLIN M&E Technology Co., Ltd.

Xulosa

V shaklidagi quruq sovutish tizimlari turli ilovalarda samarali va barqaror issiqlik tarqalishi uchun jozibali yechim taklif qiladi. Ularning afzalliklari, ilovalari va amalga oshirish masalalarini tushunib, siz sovutish ehtiyojlarini optimallashtirish va yanada barqaror kelajakka hissa qo'shish uchun ongli qarorlar qabul qilishingiz mumkin. kabi nufuzli yetkazib beruvchi bilan bog'laning Shanxay SHENGLIN M&E Technology Co., Ltd ekspert maslahati va yuqori sifatli mahsulotlar uchun.