หอทำความเย็นไหลทวนแบบปิด: คู่มือฉบับสมบูรณ์ ทำความเข้าใจประสิทธิภาพและประสิทธิผลของ a หอทำความเย็นทวนกระแสแบบปิด เป็นสิ่งสำคัญสำหรับการใช้งานในอุตสาหกรรมต่างๆ คู่มือนี้ให้ภาพรวมโดยละเอียดเกี่ยวกับการออกแบบ การใช้งาน ข้อดี และข้อควรพิจารณา เราจะสำรวจว่าระบบเหล่านี้แตกต่างจากระบบ open-loop อย่างไร และเจาะลึกถึงปัจจัยที่มีอิทธิพลต่อประสิทธิภาพการทำงาน

คูลลิ่งทาวเวอร์แบบไหลทวนแบบปิดคืออะไร?

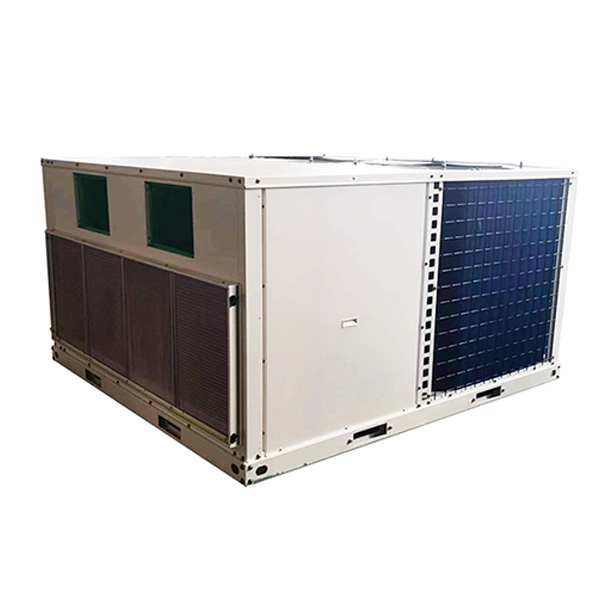

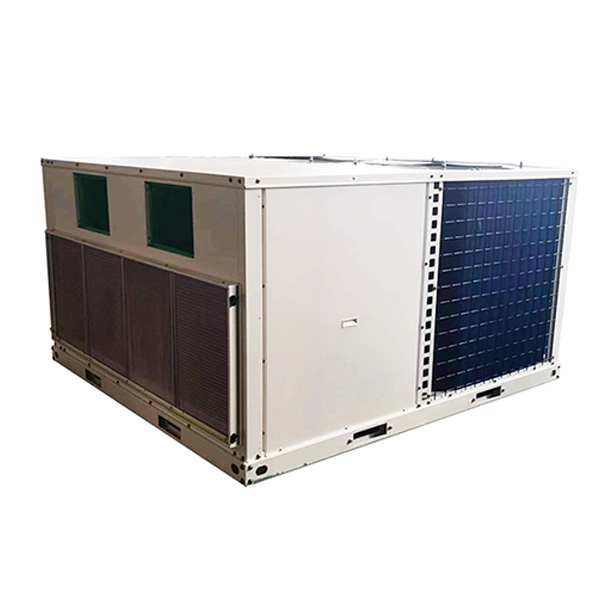

A หอทำความเย็นทวนกระแสแบบปิด เป็นหอหล่อเย็นประเภทหนึ่งที่ใช้ระบบวงรอบปิดเพื่อทำน้ำเย็น ต่างจากหอทำความเย็นแบบเปิดซึ่งปล่อยน้ำสู่ชั้นบรรยากาศโดยตรง ระบบปิดใช้ตัวแลกเปลี่ยนความร้อนเพื่อถ่ายเทความร้อนจากน้ำในกระบวนการไปยังวงจรรองของน้ำ จากนั้นจะถูกทำให้เย็นลงผ่านการระเหยและการสัมผัสอากาศ การออกแบบการไหลทวนนี้รับประกันการถ่ายเทความร้อนที่เหมาะสมโดยปล่อยให้น้ำร้อนและอากาศเย็นไหลไปในทิศทางตรงกันข้าม ระบบนี้ลดการสูญเสียน้ำและลดความเสี่ยงของการปนเปื้อน ทำให้เหมาะสำหรับการใช้งานที่ต้องการความบริสุทธิ์ของน้ำสูงหรือทรัพยากรน้ำที่จำกัด

ส่วนประกอบสำคัญของคูลลิ่งทาวเวอร์แบบไหลทวนแบบปิด

A หอทำความเย็นทวนกระแสแบบปิด โดยทั่วไปประกอบด้วยองค์ประกอบหลักหลายประการ: เครื่องแลกเปลี่ยนความร้อน: นี่คือองค์ประกอบหลักที่รับผิดชอบในการถ่ายเทความร้อนจากน้ำในกระบวนการผลิตไปยังวงจรน้ำทุติยภูมิ สามารถใช้ตัวแลกเปลี่ยนความร้อนประเภทต่างๆ (เช่น แผ่น เปลือก และท่อ) ได้ ขึ้นอยู่กับความต้องการเฉพาะของการใช้งาน พัดลม: พัดลมจะหมุนเวียนอากาศผ่านคอยล์ทำความเย็น อำนวยความสะดวกในกระบวนการระเหยและทำให้น้ำทุติยภูมิเย็นลง ประเภทของพัดลมจะแตกต่างกันไป ซึ่งส่งผลต่อประสิทธิภาพและระดับเสียง คอยล์เย็น: คอยล์เหล่านี้เป็นจุดที่การแลกเปลี่ยนความร้อนเกิดขึ้น การออกแบบส่งผลโดยตรงต่อประสิทธิภาพของหอคอย ปั๊มน้ำ: ปั๊มจะหมุนเวียนทั้งน้ำในกระบวนการผลิตและน้ำรองภายในวงจรตามลำดับ อ่างน้ำ: รวบรวมน้ำสำรองเพื่อการหมุนเวียน สื่อเติม: ในบางการออกแบบ สื่อเติมจะช่วยเพิ่มพื้นที่ผิวเพื่อการถ่ายเทความร้อนและมวลอย่างมีประสิทธิภาพ

ข้อดีของคูลลิ่งทาวเวอร์แบบไหลทวนแบบปิด

ระบบวงปิดมีข้อดีหลายประการ: ลดการใช้น้ำ: มีการสูญเสียน้ำเนื่องจากการระเหยน้อยลงอย่างเห็นได้ชัด เมื่อเทียบกับหอทำความเย็นแบบเปิด ปรับปรุงคุณภาพน้ำ: ลดความเสี่ยงในการปนเปื้อน ซึ่งสำคัญมากสำหรับการใช้งานที่ต้องการความบริสุทธิ์ของน้ำสูง การบำรุงรักษาต่ำ: ปัญหาการปรับขนาดและการกัดกร่อนน้อยลงเนื่องจากการสัมผัสกับมลพิษในชั้นบรรยากาศลดลง ผลกระทบต่อสิ่งแวดล้อมลดลง: การใช้น้ำน้อยลงและการปล่อยก๊าซเรือนกระจกในอากาศที่ลดลงส่งผลให้ผลกระทบต่อสิ่งแวดล้อมน้อยลง ปรับปรุงประสิทธิภาพ: การออกแบบ Counterflow ช่วยเพิ่มประสิทธิภาพการถ่ายเทความร้อนให้สูงสุด

ข้อเสียของคูลลิ่งทาวเวอร์แบบไหลทวนแบบปิด

แม้ว่าจะมีข้อดีหลายประการ แต่ระบบปิดก็ยังมีข้อเสียอยู่บ้าง: ต้นทุนเริ่มต้นที่สูงขึ้น: เมื่อเปรียบเทียบกับหอทำความเย็นแบบเปิด โดยทั่วไปการลงทุนเริ่มแรกจะสูงกว่าเนื่องจากความซับซ้อนที่เพิ่มขึ้นของเครื่องแลกเปลี่ยนความร้อนและระบบวงรอบปิด ความซับซ้อนที่เพิ่มขึ้น: ระบบต้องการการตรวจสอบและบำรุงรักษาที่ซับซ้อนมากขึ้น เนื่องจากมีส่วนประกอบหลายชิ้น ศักยภาพในการรั่วไหล: ระบบวงปิดทำให้เกิดการรั่วไหล โดยต้องมีการตรวจสอบและบำรุงรักษาอย่างระมัดระวัง

การเลือกคูลลิ่งทาวเวอร์แบบไหลย้อนแบบปิดที่เหมาะสม

การเลือกที่เหมาะสม หอทำความเย็นทวนกระแสแบบปิด ต้องพิจารณาปัจจัยหลายประการอย่างรอบคอบ รวมถึง: ความสามารถในการทำความเย็น: ความสามารถในการทำความเย็นที่ต้องการจะกำหนดขนาดและประเภทของทาวเวอร์ที่ต้องการ ข้อกำหนดด้านคุณภาพน้ำ: ข้อกำหนดด้านความบริสุทธิ์ของน้ำในกระบวนการจะส่งผลต่อการออกแบบและการเลือกใช้วัสดุของระบบ ข้อพิจารณาด้านสิ่งแวดล้อม: ควรพิจารณากฎระเบียบเฉพาะสถานที่และข้อกังวลด้านสิ่งแวดล้อม งบประมาณ: จำเป็นต้องคำนึงถึงต้นทุนการลงทุนเริ่มแรก รวมถึงค่าบำรุงรักษาและการดำเนินงานอย่างต่อเนื่องในการตัดสินใจ

การใช้งานของคูลลิ่งทาวเวอร์แบบไหลทวนแบบปิด

อาคารเหล่านี้พบการใช้งานในอุตสาหกรรมต่างๆ ที่การควบคุมอุณหภูมิที่แม่นยำและการอนุรักษ์น้ำเป็นสิ่งสำคัญยิ่ง: การผลิตไฟฟ้า: คอนเดนเซอร์ทำความเย็นในโรงไฟฟ้า กระบวนการทางเคมี: การควบคุมอุณหภูมิในปฏิกิริยาเคมี ระบบ HVAC: ทำความเย็นให้กับอาคารขนาดใหญ่และโรงงานอุตสาหกรรม การผลิต: เครื่องจักรและอุปกรณ์ทำความเย็น ศูนย์ข้อมูล: การรักษาอุณหภูมิที่เหมาะสมที่สุดสำหรับอุปกรณ์อิเล็กทรอนิกส์ที่มีความละเอียดอ่อน

Shanghai SHENGLIN M&E Technology Co., Ltd. - พันธมิตรของคุณในโซลูชั่นการทำความเย็น

หากต้องการโซลูชันหอหล่อเย็นคุณภาพสูงและมีประสิทธิภาพ โปรดพิจารณา Shanghai SHENGLIN M&E Technology Co., Ltd.. ความเชี่ยวชาญในการออกแบบและการผลิตหอทำความเย็นแบบกำหนดเองทำให้มั่นใจได้ถึงประสิทธิภาพและความน่าเชื่อถือสูงสุดสำหรับการใช้งานที่หลากหลาย

การเปรียบเทียบคูลลิ่งทาวเวอร์แบบเปิดและแบบปิด

| คุณสมบัติ | เปิดคูลลิ่งทาวเวอร์ | หอหล่อเย็นแบบปิด ||—————–|——————————————-|——————————————|||| การใช้น้ำ | สูง | ต่ำ || คุณภาพน้ำ | ไวต่อการปนเปื้อน | รักษาความบริสุทธิ์สูง || ต้นทุนเริ่มต้น | ล่าง | สูงกว่า || การบำรุงรักษา | สูงกว่า (การปรับขนาด การกัดกร่อน) | ล่าง || ผลกระทบต่อสิ่งแวดล้อม | สูงกว่า (การใช้น้ำ, การปล่อยก๊าซเรือนกระจกในอากาศ) | ล่าง || ประสิทธิภาพ | ด้านล่าง (ขึ้นอยู่กับการออกแบบ) | โดยทั่วไปจะสูงกว่า (การออกแบบทวนกระแส) | ตาราง { ความกว้าง: 700px; ระยะขอบ: 20px อัตโนมัติ; ยุบเส้นขอบ: ยุบ;} th, td { เส้นขอบ: 1px ทึบ #ddd; ช่องว่างภายใน: 8px; การจัดแนวข้อความ: left;}th { สีพื้นหลัง: #f2f2f2;}

ข้อมูลนี้มีไว้เพื่อเป็นแนวทางทั่วไปเท่านั้น ปรึกษากับผู้เชี่ยวชาญหอทำความเย็นสำหรับข้อกำหนดการใช้งานเฉพาะ