Drycoolers geus jadi unsur pivotal dina prakték industri sustainable. Nalika masalah lingkungan ningkat, industri beuki narik kana solusi sapertos ieu pikeun pendinginan anu efisien sareng ramah lingkungan. Acan, misconceptions persist ngeunaan aplikasi tur mangpaat maranéhanana.

Ngarti Drycoolers dina Praktek

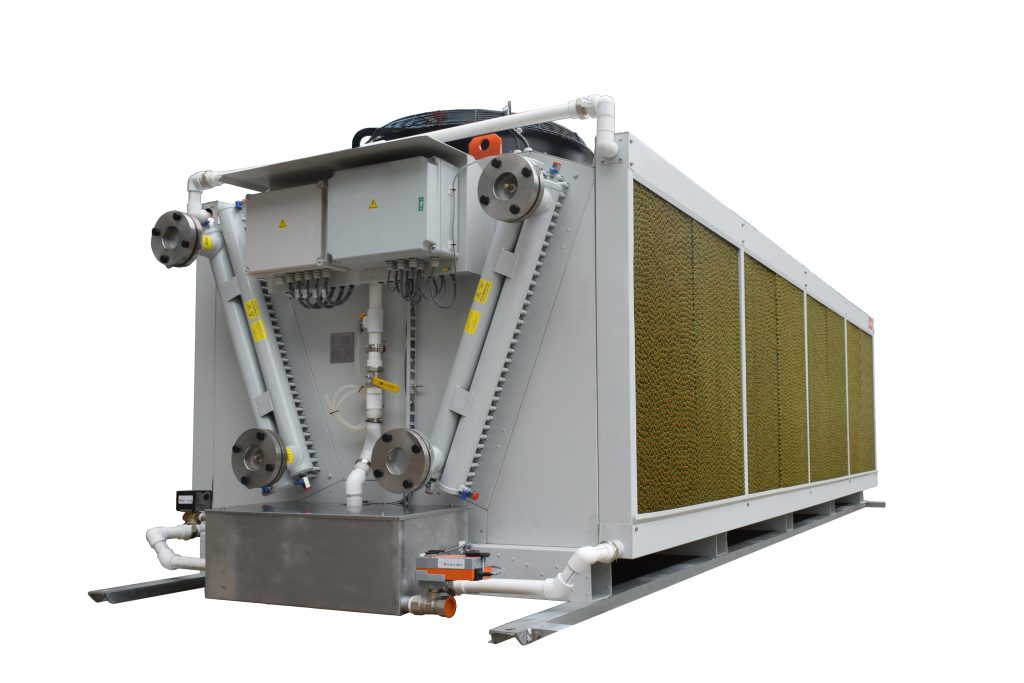

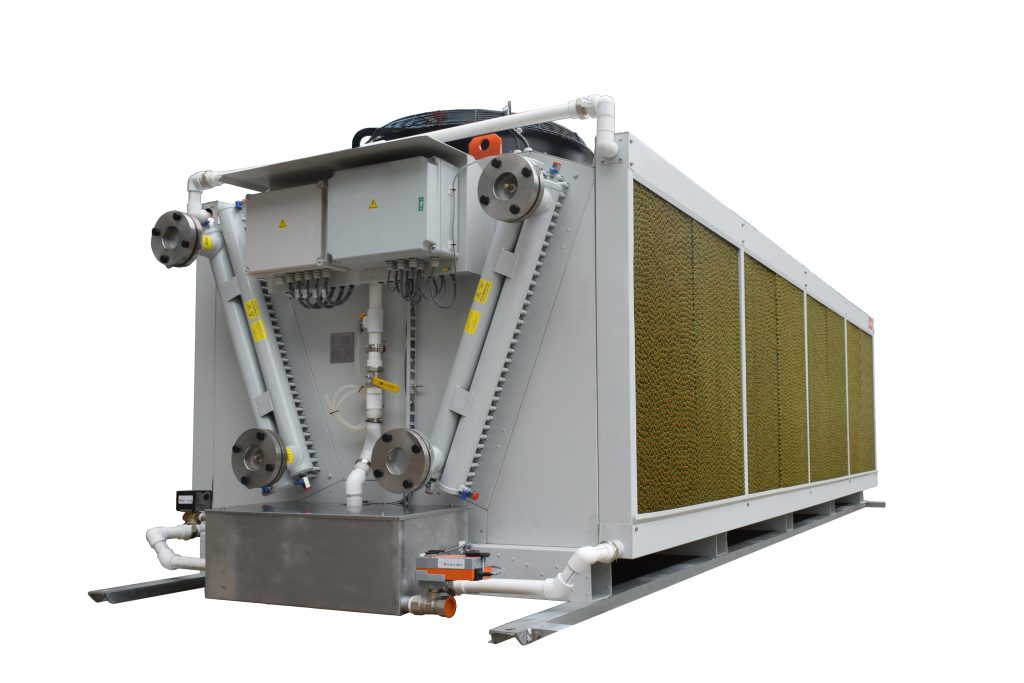

Dina seueur setélan industri, kabutuhan cooling penting pisan. Métode penyejukan tradisional sering ngagunakeun cai anu ageung, ningkatkeun biaya operasional sareng masalah lingkungan. Di dieu, drycoolers lengkah salaku alternatif sustainable. Sistem ieu ngagunakeun hawa sareng cai minimal, ngajantenkeun aranjeunna langkung efisien sumber daya.

Hayu atuh elaborate kalawan kaayaan tina pangalaman kuring. Klién di séktor manufaktur berjuang ngalawan pamakean cai anu luhur sareng sistem pendinginan konvensional. Saatos ngalih ka drycoolers ti SHENGLIN, aranjeunna henteu ngan ukur ngirangan konsumsi cai tapi ogé ningali turunna tagihan énergi.

Prinsipna lugas: ku langkung ngandelkeun hawa pikeun niiskeun, drycoolers nawiskeun kauntungan ganda - ngirangan pamakean sumber daya bari nurunkeun émisi anu aya hubunganana sareng produksi énergi. Ieu aligns sampurna jeung tujuan kelestarian global, sarta éta hiji hal anu teu bisa overstated dina bentang industri kiwari.

Pangaruh kana Efisiensi Operasional

A skepticism umum sabudeureun drycoolers nyaeta kamampuan maranéhanana dina skenario paménta tinggi. Bakal aranjeunna nanganan panas, sacara harfiah na figuratively? encounters praktis abdi nyarankeun aranjeunna tiasa, tur rada éféktif.

Contona, dina mangsa proyek sareng pabrik pangolahan kimiawi merlukeun cooling konsisten pikeun operasi optimal, urang terpadu sistem drycooler ngaropéa ku SHENGLIN. Henteu ngan éta minuhan paménta, tapi ogé dioperasikeun ku downtime pangropéa ngurangan dibandingkeun urut munara cooling maranéhna.

Efisiensi operasional ieu sanés ngan ukur ngeunaan kinerja. Éta ditarjamahkeun kana pangsaeutikna gangguan, umur alat anu langkung panjang, sareng pamustunganana, penghematan biaya anu ageung. Nalika timbangan kelestarian, faktor-faktor ieu penting pisan.

Kesederhanaan sareng Adaptasi

Bisa jadi heran ngeunaan praktis tina integrasi drycoolers kana sistem aya. Éta mangrupikeun perhatian anu sah, khususna pikeun industri anu gaduh infrastruktur anu mapan. Nanging, dina pangalaman kuring, aranjeunna tiasa adaptasi pisan.

Dina situs konstruksi, kalenturan tina drycoolers diwenangkeun pikeun integrasi seamless kana kerangka aya tanpa merlukeun alterations éksténsif. Kesederhanaan ieu dina adaptasi henteu ngan ukur ngahemat waktos tapi sacara signifikan ngirangan biaya palaksanaan awal, faktor anu seueur anu teu ditingali nalika nimbangkeun balik kana investasi.

Kauntungannana ngaleuwihan betah instalasi. Coolers ieu dirancang pikeun ngajalankeun éfisién dina kaayaan iklim variatif, ningkatkeun versatility maranéhanana sarta wengkuan aplikasi.

Ngarengsekeun Misconceptions Industri

Sering aya anggapan yén drycoolers ngan ukur cocog pikeun lingkungan anu langkung hampang. Dina kanyataanana, kamajuan téhnologis geus nyata dimekarkeun rentang kamampuhan maranéhanana. Anggapan salah ieu tetep sabagean kusabab inpormasi luntur sareng sabagean kusabab résistansi kana parobahan.

Nalika damel sareng produsén tékstil di daérah anu panas sareng gersang, kami ngabuktikeun yén drycooler tiasa dianggo sacara efektif sanajan dina zona suhu luhur. Koncina nyaéta nyaluyukeun solusi pikeun nyocogkeun kana tungtutan lingkungan, hiji hal anu unggul ku SHENGLIN ngaliwatan kaahlianna dina téknologi pendinginan industri.

Ngadidik pamangku kapentingan ngeunaan nuansa ieu penting pisan. Industri kedah diinpokeun ngeunaan kumaha drycoolers modern tiasa di-tweake sareng disaluyukeun pikeun nyumponan kabutuhan operasional khusus tanpa ngorbankeun kelestarian.

Aplikasi dunya nyata sareng Outlook Kahareup

Hayu urang toél kana aplikasi dunya nyata. Kuring geus katempo drycoolers dilaksanakeun teu ngan di industri beurat tapi ogé di séktor kawas puseur data, dimana efisiensi cooling sarta kelestarian anu Cangkuang. Salaku conto, SHENGLIN parantos suksés nerapkeun solusi mutakhir dina sagala rupa séktor, negeskeun kaahlianana.

Tren anu langkung lega nunjukkeun kana paningkatan téknologi anu lestari sapertos kitu. Nalika peraturan lingkungan ketat, industri milarian cara pikeun nyaluyukeun prakték operasional sareng syarat ieu, sareng drycoolers maénkeun peran sentral.

Tren ieu, kuring yakin, bakal diteruskeun nalika industri sareng pamaréntahan nyorong prakték anu langkung héjo. Tangtanganna bakal aya dina kustomisasi sareng pendidikan-mastikeun unggal sistem disaluyukeun sareng lingkunganana sareng pangguna ngartos poténsi pinuh na. Nganjang ka Shanghai SHENGLIN M&E Technology Co.,Ltd di ShenglinCoolers.com pikeun langkung seueur wawasan ngeunaan kamajuan ieu.