Modular Data Center Container Benefits: Beyond the Hype

When you hear modular data center container, the immediate image is a shipping crate stuffed with servers, a plug-and-play utopia. That’s the sales pitch, but the real benefits—and the real headaches—are more nuanced. It’s not just about speed, though that’s a huge part. It’s about rethinking the entire deployment and lifecycle model. I’ve seen projects where the container itself was the easy part; the real work was in the site prep, the power distribution nuances, and the thermal management assumptions that looked great on paper. Let’s cut through the generic bullet points.

The Tangible Speed Advantage and Its Caveats

The primary driver is, undeniably, rapid deployment. We’re talking about taking a project from a multi-year construction cycle down to, in some cases, under six months from order to operation. This is a game-changer for edge computing rollouts or disaster recovery scenarios. I recall a project for a telecom client needing to deploy capacity in a remote region; a traditional build was impossible within their timeframe. The containerized solution got them online in 16 weeks. But here’s the catch: that timeline assumes your site is ready. Ready means a massive, perfectly level concrete pad, utility hookups within a stone’s throw, and all permits sorted. If those aren’t locked down, your shiny container becomes a very expensive storage unit.

This speed also translates to scalability. The modular bit is key. You can incrementally add capacity in discrete, predictable chunks—order another 500kW pod when you need it, not when the CFO approves a whole new building. It de-risks capacity planning. However, this modularity requires foresight in initial design. Are your interconnects between modules standardized? How does network fabric scale? I’ve seen setups where adding a second container created a latency nightmare because the spine-leaf topology wasn’t considered from day one.

Then there’s the testing benefit, often overlooked. A Modular faʻamaumauga nofoaga can be fully assembled, cabled, and tested at the factory—like Shanghai Shenglin M & E Tekonolosi Co., Ltd does with their integrated cooling systems. You’re not trying to troubleshoot a faulty PDU or a coolant leak with electricians and IT guys tripping over each other on a live construction site. You get a known-good unit. But factory acceptance testing is only as good as the test regimen. Insist on witnessing it.

Thermal Management: The Make-or-Break Detail

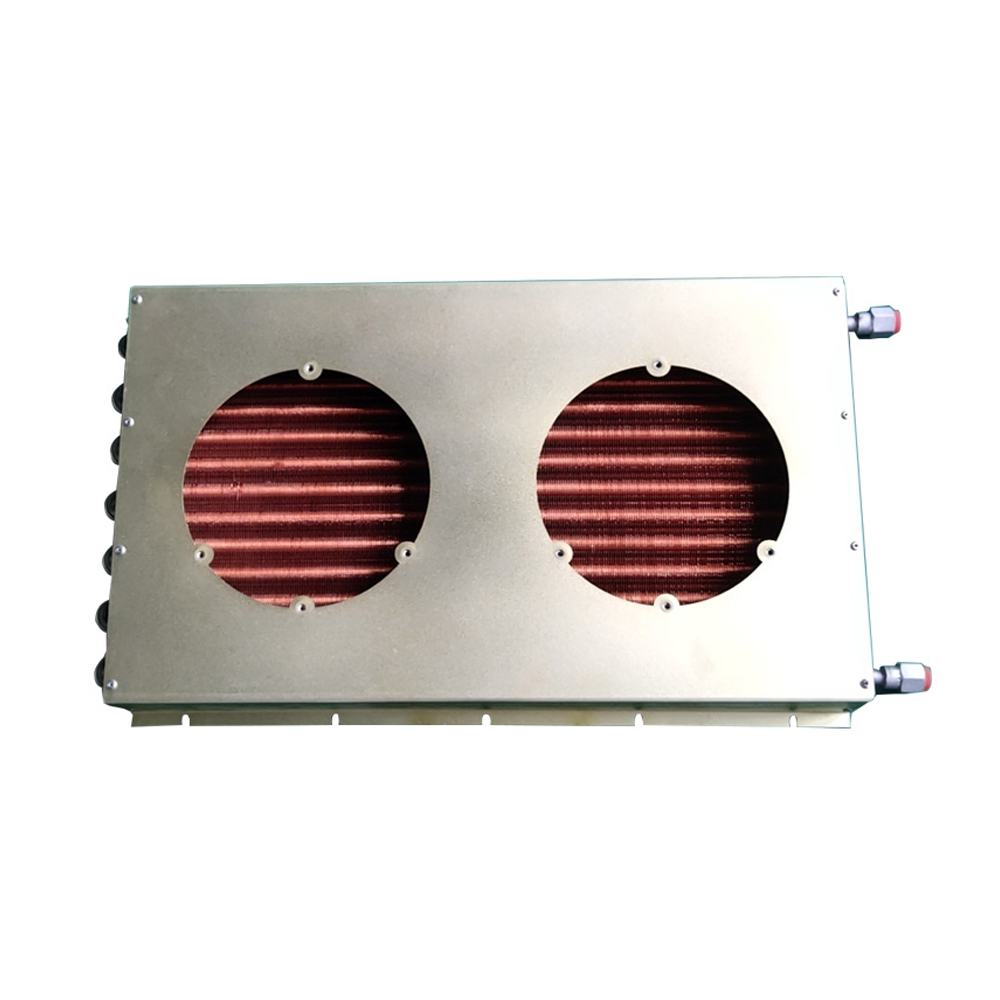

This is where the rubber meets the road. The compact, high-density nature of containers makes cooling efficiency critical and challenging. The benefit touted is optimized, purpose-built cooling. In reality, you’re choosing a path: in-row cooling, overhead chilled water, or rear-door heat exchangers. Each has trade-offs. I’m a fan of rear-door heat exchangers for their simplicity and how they contain the hot aisle, but they require a robust chilled water supply. If your site’s water quality is poor, you’re in for a world of maintenance pain.

Companies that deeply understand industrial thermal dynamics, like SHENGLIN (you can see their approach at https://www.shenglincoolers.com), bring a practical edge. Their background in industrial cooling tech means they think in terms of reliability and mean time between failures (MTBF) for pumps and fans, not just BTU ratings. This is crucial. A container’s cooling system failing is a catastrophic event; redundancy is non-negotiable. I’ve seen a design that saved costs by using a single loop for multiple cooling units; a single point of failure that nearly caused a meltdown during a pump seizure.

The benefit here is potential for higher Power Usage Effectiveness (PUE) in a controlled, sealed environment. But you must actively manage it. Airflow sealing is everything. A missing blanking plate or a poorly sealed cable penetration can completely derail your thermal model. It’s not a set and forget system; it requires the same vigilance as a room, just in a smaller, more volatile package.

Total Cost of Ownership: A Complicated Picture

The Capex story is straightforward: often lower upfront than brick-and-mortar, especially when you factor in avoided architectural and civil engineering costs. But the real analysis is in the Opex. The benefit can be positive, but it’s fragile. Power efficiency, as mentioned, can be excellent. However, maintenance logistics are different. Sending a technician to a remote container site is expensive. You need components that are easily swappable by a junior engineer. Think hot-swappable fan trays, modular power supplies.

There’s also the lifespan consideration. A building might last 30 years. A container structure, even with robust corrosion treatment, has a different fatigue profile, especially if it’s moved. The data center container itself might be a 15-year asset, while the IT inside refreshes every 3-5 years. Your design must allow for complete IT gut-and-replace without compromising the shell’s integrity. I was involved in a refresh where we had to cut new cable penetrations because the original layout couldn’t accommodate newer, wider switches. Plan for unknown future cable densities.

Then there’s the residual value. A benefit some vendors push is redeployability. The idea that you can just ship a full container to a new location. In practice, this is rarely economical. The cost of decommissioning, safe transport, and recommissioning often rivals just deploying new. The real residual value is in the reusability of the design and the knowledge, not necessarily the physical box.

Logistical and Site Flexibility: Reality vs. Marketing

Deploy anywhere is the slogan. The reality is deploy on many more sites than before. You still need a stable foundation, substantial power access, and fiber connectivity. The benefit is that you can use a brownfield site, a parking lot, or a rooftop that couldn’t support a traditional build. This unlocks urban edge locations. We placed one on a reinforced warehouse rooftop, something a built-out room could never have done.

But flexibility has limits. Once placed, these are not meant to be mobile. The internal infrastructure—busbars, rigid piping, raised floor (if used)—isn’t designed for repeated movement. The container is a structural form factor, not a shipping crate. I learned this the hard way early on, agreeing to a temporary placement with a future move in mind. The move cost 40% of the original unit price due to the extensive de-integration required.

Another flexibility aspect is vendor lock-in. A purpose-built container from a major OEM can be a turnkey dream, but you’re tied to their service and future upgrades. A roll-your-own approach using a generic container shell and integrating best-of-breed components (like cooling from a specialist such as SHENGLIN, who focuses on industrial cooling technologies) offers more control but demands strong integration project management. There’s no single right answer, only a right answer for your team’s skills and risk tolerance.

The Human Factor: Operations and Culture

This is the most underestimated aspect. The operational benefit of a Modular faʻamaumauga nofoaga is standardization. Every pod looks the same, which should simplify procedures. But if your team is used to walking into a vast white space, working in a narrow, sometimes noisy, container is a cultural shift. Access control, safety (egress in case of fire), and even where technicians put their tools need rethinking.

Monitoring becomes paramount. You need granular sensor data—not just inlet temps, but differential pressure across coils, vibration on pumps, corrosion sensors if near a coast—all integrated into your DCIM. The benefit is that you get a more complete picture of your infrastructure health than in many legacy rooms. This data allows for predictive maintenance, which is essential for remote sites.

Finally, there’s a psychological benefit. These projects can move fast. They feel agile. That momentum can break through organizational inertia that often plagues large construction projects. But it requires a empowered, cross-functional team—facilities, IT, network, and procurement—working in lockstep from the beginning. If those groups still operate in silos, the benefits of the container will be eroded by internal friction. The technology is only half the solution; the operational model is the other. In the end, the container doesn’t run your IT. Your people do, and the container just gives them a different, sometimes better, sometimes more demanding, toolbox to work with.