Look, everyone wants better efficiency from their air-cooled heat exchangers, but most jump straight to fan upgrades or cleaning schedules. The real gains often hide in the details you only see after years on site—like how a slightly off pitch on a single fin tube bundle can throw your entire thermal profile out of whack, or why the standard annual cleaning mantra is sometimes a fast track to wasted money and new problems. Let’s cut through the generic advice.

The Baseline: It’s Never Just About Airflow

I see this all the time. A plant manager points to a fin fan bank and says, We need more airflow, let’s spec a higher RPM motor or bigger fan. That’s a classic misstep. More airflow often means more power draw, higher noise, and increased vibration without a guaranteed return on cooling duty. The first question should always be: is the existing airflow being used effectively? I recall a glycol cooler in a petrochemical unit where they’d installed high-performance fans but were baffled by stagnant outlet temps. The issue wasn’t the fan; it was the air recirculation because the plenum seals had degraded. Hot exhaust was just getting sucked back in. We fixed the sealing with some basic sheet metal work and saw a 7°C drop in process outlet temperature. No new hardware.

Efficiency starts with system thinking. You have to consider the triad: airside performance, tubeside performance, and the mechanical condition. If you optimize one in isolation, you might be creating a bottleneck elsewhere. For instance, a perfectly clean fin surface is useless if the internal tubes are scaled up. You need a balanced approach.

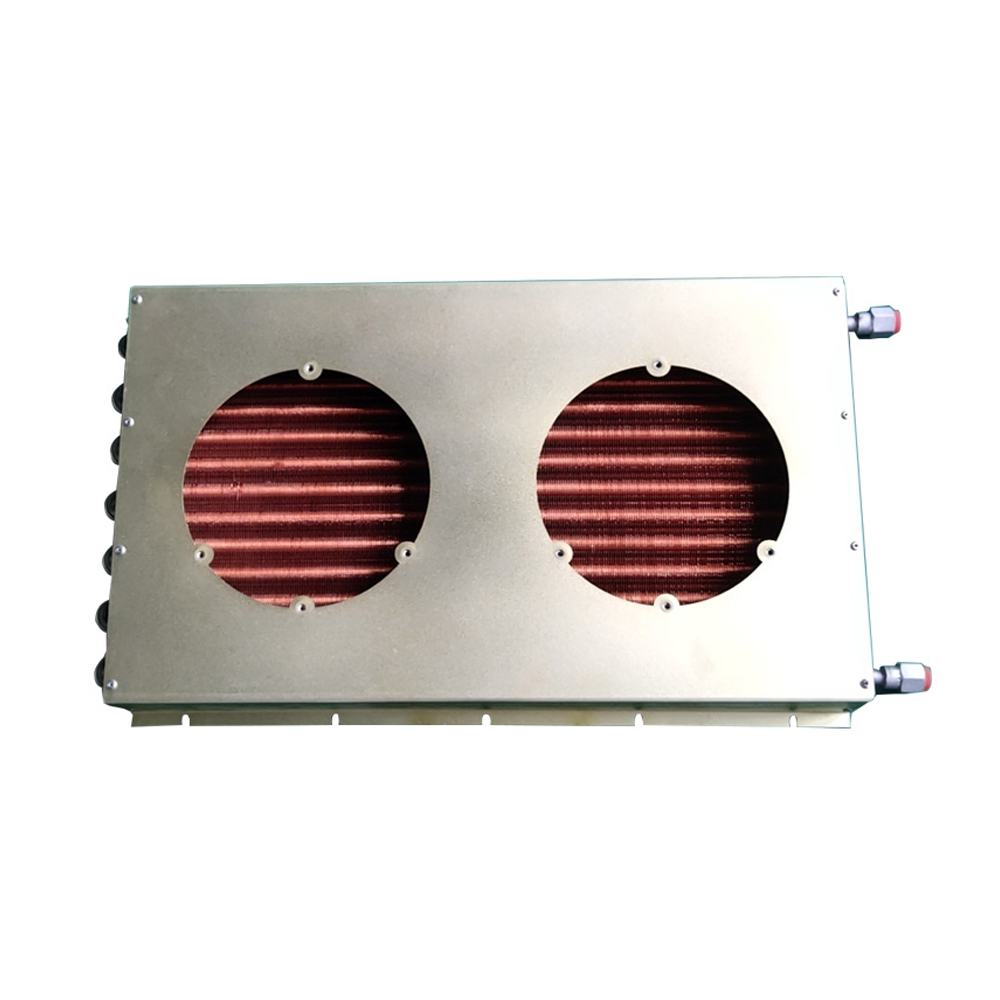

And don’t trust design conditions as your eternal truth. They’re a snapshot. I was reviewing a cooler from a reputable manufacturer—let’s say a company like Shanghai SHENGLIN M&E Technology Co.,Ltd, known for their industrial coolers—and the design was sound. But on-site, the ambient air temperature profile was completely different from the original spec due to new structures built nearby. The cooler was essentially operating in a hot air pocket. We had to model the actual ambient conditions, not the textbook ones, to diagnose the shortfall. Their website, https://www.shenglincoolers.com, lists solid engineering specs, but even the best design needs field validation against real-world conditions.

Cleaning: The Double-Edged Sword

This is where well-intentioned maintenance can backfire. Yes, fouled fins kill efficiency. But aggressive cleaning kills fins. I’ve seen bundles where the fins were literally bent over or eroded from high-pressure water or improper chemical washes. The loss of fin surface area is permanent. The goal is to restore thermal contact, not to make the bundle look brand new.

We developed a simple rule: test-clean a small section. Use low-pressure water (I prefer below 700 psi) with a wide fan tip, and always spray perpendicular to the fin faces. If you see dirt coming off but the fins stay straight, you’re good. If you need chemicals, know your fin material. Aluminum fins with acid wash? You’re playing with fire unless you have a perfect neutralization protocol. Sometimes, a soft bristle brush and compressed air for dry dust is all you need. It’s less impressive-looking but preserves the asset.

Frequency is another trap. I worked at a fertilizer plant that cleaned every quarter religiously. After a review, we found the fouling rate was very low for 8 months, then spiked during a specific production campaign. We shifted to condition-based monitoring using a simple infrared gun to track tube skin temperature against a clean baseline. We extended cleaning intervals by 5 months, saving on water, labor, and reducing the mechanical wear on the bundles. The key is monitoring, not a calendar.

The Fan & Drive Assembly: Subtle Losses Add Up

Everyone checks fan blades for damage, but what about the hub? A corroded or imbalanced hub transfers vibration that wastes energy and stresses the gearbox. We had a case of high amp draw on a motor. Replaced the motor, no change. Re-aligned the drive, minor improvement. Finally, after pulling the fan, we found the hub’s internal taper lock bushing was slightly fretted. It was causing just enough slip to reduce effective pitch, forcing the motor to work harder. A $200 part was causing thousands in extra energy cost per year.

Belts and sheaves are the usual suspects, but they’re often set and forgotten. A belt that’s too tight increases bearing load; too loose causes slip and heat. The thumb rule for deflection is okay, but using a sonic tension tester is better. And match your belts—don’t just throw on a new one with an old set. Mixed belts share load unevenly. I keep a kit from a specific manufacturer for critical units because inconsistent belt quality is a real headache.

Then there’s the fan tip clearance. This is a big one. The gap between the fan blade tip and the fan shroud. If it’s too large, air leaks back, reducing effective thrust. The target is usually under 0.5% of the fan diameter, but you’d be surprised how many units run at 1% or more due to shroud deformation or improper assembly. Measuring it requires some ingenuity with feeler gauges, but tightening that gap is a pure, no-cost efficiency win.

Process Side: The Forgotten Half of the Equation

We obsess over airside, but the tubeside dictates the heat load. If your process flow rate is lower than design, or the inlet temperature is higher, no amount of airside tweaking will hit the target. You need to know your actual duty. Installing permanent temperature and pressure gauges on the inlet and outlet headers is worth its weight in gold for diagnostics.

Fluid velocity matters. Too low, and you get stratification and fouling; too high, and you get erosion. I remember a solvent cooler where the tubeside pressure drop was creeping up. The instinct was to think of scaling. Turns out, a flow control valve upstream was failing and restricting flow, lowering velocity, which then allowed a soft polymer to deposit in the tubes. We fixed the valve and flushed the tubes. The problem wasn’t the cooler’s efficiency; it was the process condition forcing inefficiency onto it.

Control Logic: Don’t Let Automation Sleep

Modern units have variable frequency drives (VFDs) and louvers. But the control logic is often primitive—say, a simple temperature setpoint that ramps all fans up and down in unison. In a bank of multiple cells, this can be wasteful. Staggering the startup of fans or implementing a lead/lag strategy based on actual ambient wet-bulb temperature can save significant power.

A project with a multi-cell forced draft cooler for a compressor aftercooler taught me this. We programmed the VFDs to maintain a specific process outlet temperature by only adjusting the speed of two out of four fans under normal conditions. The other two remained off or at minimum speed. The lead fans did most of the work. We only brought the lag fans online during the hottest part of the day or during peak load. The energy savings were around 18% annually. The hardware was capable, but the original control philosophy wasn’t optimized.

Also, check your temperature sensor placement. If it’s in a spot with poor airflow or sun exposure, you’re getting a false reading, and your control system is making decisions based on a lie. Insulate sensor lines and consider radiation shields.

The Good Enough Mindset & When to Call It

Finally, know when to stop. Pursuing the last 2% of theoretical efficiency might require a full bundle replacement or a complete mechanical overhaul that has a 20-year payback. That’s not engineering; that’s accounting. Sometimes, the most efficient decision is to maintain a unit at a good enough level while planning for its eventual replacement with a better-designed system.

I’ve consulted on units that were patched and tweaked for decades. At some point, the cumulative efficiency losses from bent fins, tube blockages, and outdated fan design make retrofitting a losing battle. Companies like SHENGLIN, which specialize in industrial cooling technologies, often provide retrofit assessments that can be more valuable than a piecemeal fix. A new bundle with enhanced fin design (like crimped spiral fins vs. plain) or a more aerodynamic fan package can be a capex project, but the ROI can be clear if your existing unit is truly at the end of its effective life.

So, my core tip? Treat your fin fan cooler as a living system. Listen to it (literally, listen for vibration), measure it with simple tools, and intervene based on data and a holistic view, not just a maintenance checklist. The biggest gains come from understanding the interaction between all its parts, not from chasing a single magic bullet.