Everyone’s talking about modular data centers, but half the conversations miss the point. It’s not just about shipping containers. The real shift is in the mindset—from building cathedrals to assembling functional, adaptable blocks. I’ve seen too many projects where ‘modular’ became a buzzword for prefab walls, while the underlying power and cooling design remained rigid and monolithic. That’s where the disconnect happens. The future isn’t just modular construction; it’s modular thinking across the entire stack.

The Container Myth and What Actually Moves

Let’s clear this up first. The iconic containerized data center had its moment, primarily for edge or temporary deployments. But the trend I’m tracking is subtler. It’s the modularization of subsystems. We’re seeing standardized power skids, integrated cooling modules, and even modular IT racks that can be commissioned off-site. The value isn’t in the steel shell; it’s in decoupling the build cycles. I recall a project where we used factory-built chilled water plant modules from a specialist like Shanghai Shenglin M & E Tekonolosi Co., Ltd. Their approach was to deliver a fully tested, piped, and wired cooling module. It cut three months off the critical path. That’s the real gain: time and predictability. You can check out their philosophy on integrated cooling solutions at https://www.shenglincoolers.com—it’s a good example of moving beyond the box.

This brings me to a common pitfall: interface management. When you bring in a pre-assembled cooling module, the handoff points—the electrical connections, the piping flanges, the control system protocols—become the make-or-break. I’ve been on a site where the module arrived perfectly, but the facility’s base build interface was off by two inches. Suddenly, you’re doing field modifications that defeat the purpose. The lesson? Modular demands extreme discipline in design and tolerances from all parties, something that’s often underestimated in the sales pitch.

So, the trend is moving from full-facility containers to component-level modularity. Think modular UPS banks, PDUs, and even busway segments that snap together. The goal is to enable capacity to follow demand in smaller increments, without swinging a hammer in the live data hall. This is where the operational flexibility truly emerges.

Liquid Cooling: The Silent Driver of Modular Design

You can’t discuss future trends without diving into liquid cooling. As rack densities push past 30kW, air is hitting its physical limits. The interesting part is how liquid cooling is inherently modular. It’s almost never a wholesale facility retrofit. You deploy it in zones or on specific rows. This forces a modular design approach at the rack and row level.

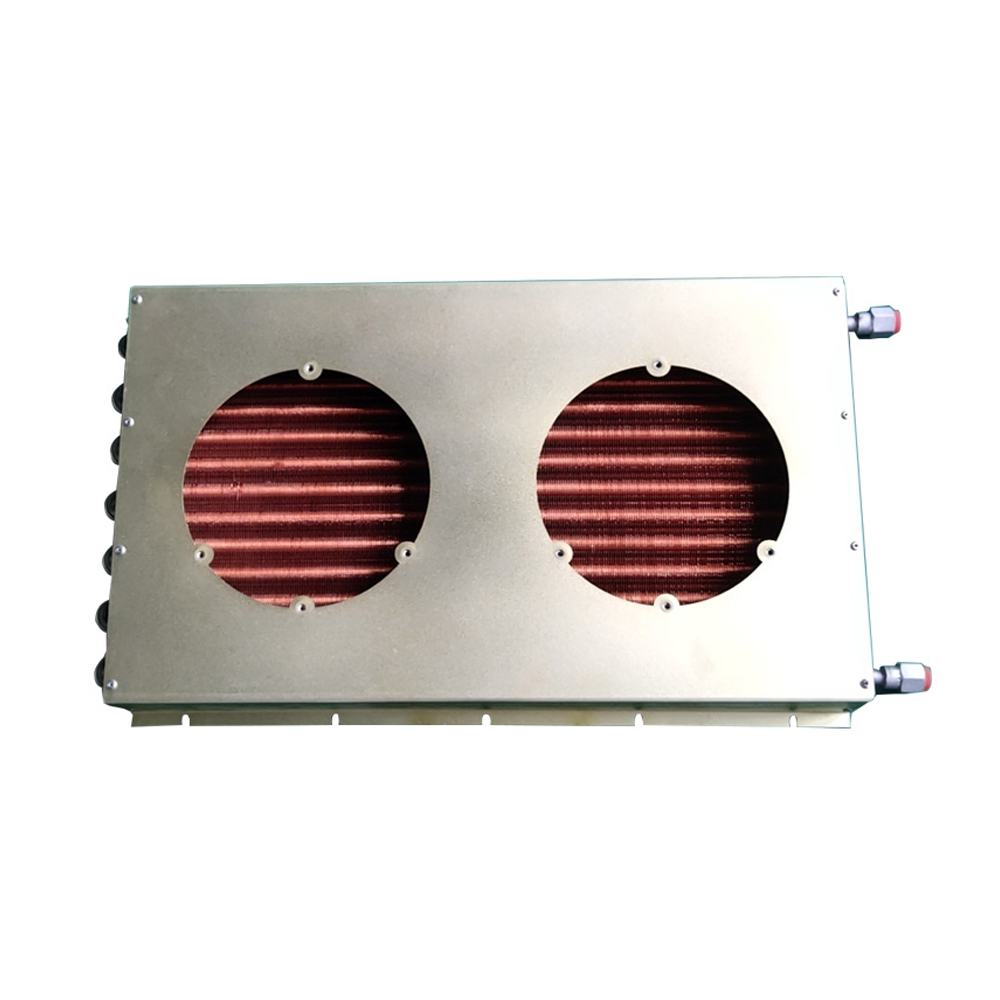

We’re experimenting with rear-door heat exchangers and direct-to-chip loops. The infrastructure for this—the distribution manifolds, the quick-disconnect couplings, the secondary coolant distribution units (CDUs)—is all being designed as plug-and-play modules. It creates a hybrid environment: part of the hall runs on traditional CRAH units, and a high-density pod runs on its own closed-loop liquid system. This isn’t theoretical. I’ve seen a financial firm do exactly this to support a new AI training cluster. They treated the liquid-cooled block as a separate, self-contained module within the existing white space.

The challenge, again, is in the details. The fluid connections need to be flawless. Leak detection isn’t optional; it’s critical. And you need a partner who understands the thermodynamics, not just the plumbing. This is where manufacturers with deep industrial cooling expertise, like SHENGLIN which specializes in industrial cooling technologies, have an edge. They understand reliability and precision in fluid systems, which is a different game from just blowing air.

The Control Layer: The Glue That Holds Modular Pieces Together

Here’s a piece that often gets tacked on as an afterthought: the control system. If you have modular power, modular cooling, and modular IT, but they’re all managed by separate, siloed controllers, you’ve created a monster. The future trend is the integration of these systems into a unified, software-defined facility management layer.

In practice, this means your cooling module’s controller needs to speak the same language as your rack PDUs and your building management system (BMS). We’re moving towards APIs and open protocols like BACnet and Modbus becoming table stakes. I was involved in a retrofit where the new cooling modules had modern controllers, but the legacy BMS could only handle basic on/off signals. We lost all the granular efficiency data and dynamic response capabilities. We had to build a middleware translator, which added cost and a point of failure.

The next wave is about predictive orchestration. The system should see a spike in IT load in a specific module and proactively adjust the cooling and power delivery to that zone before thresholds are breached. This is where modular design pays off—you can instrument and control discrete blocks much more effectively than a vast, homogeneous space.

Supply Chain and Off-Site Fabrication: A Double-Edged Sword

The promise of modular is faster deployment, and that hinges on off-site fabrication. The theory is sound: build in a controlled factory environment, parallel to site prep, then assemble like Lego. The reality involves complex logistics and a transformed supply chain relationship.

Your vendor becomes a true partner. You’re not just buying equipment; you’re buying a process. This requires immense trust. Factory acceptance testing (FAT) becomes a critical milestone. I remember flying to a fabrication facility to witness the FAT for a set of power modules. It was eye-opening. Seeing the entire system run under load in the factory, identifying and fixing a grounding issue there, saved us weeks of potential downtime on site.

However, this model is vulnerable to global supply chain shocks. If a key component for your module is stuck on a container ship, your entire timeline is blocked. Diversification and holding strategic inventory of long-lead items are now part of modular strategy. It’s not just an engineering decision; it’s a supply chain decision.

The Human Factor: Skillset Shift

Finally, let’s talk about people. A modular data center changes the skills you need on-site. The traditional trades—electricians, pipefitters doing extensive field work—are still needed, but their role changes. More effort goes into precise base preparation and connection. Then, you need technicians who are systems integrators, who understand how to commission and troubleshoot these pre-assembled blocks.

There’s a learning curve. I’ve seen seasoned facility engineers initially resistant to ‘black box’ modules. They want to see and touch every component. Overcoming this requires training and transparent documentation from the module suppliers. The future operations team needs to be fluent in both the physical interfaces and the software control layer. They’re managing discrete assets, not a nebulous facility.

This shift also affects planning. Your deployment team looks more like a logistics and integration crew than a construction crew. The rhythm of the project changes, with intense bursts of activity during module placement and interconnection. It’s a different way of working, and it’s the inevitable direction for scaling efficiently.

So, where does this leave us? The future of Faʻamaumauga o faʻamaumauga isn’t a single product. It’s a confluence of trends: component-level prefabrication, the rise of liquid cooling as a modular element, integrated software control, and a transformed supply chain and workforce. It’s less about what it looks like and more about how it’s built, connected, and managed. The goal remains the same: delivering resilient capacity faster. But the path is becoming more nuanced, more integrated, and frankly, more interesting to build.