Understanding and Optimizing Shell and Tube Evaporators

This comprehensive guide explores the design, operation, and optimization of shell and tube evaporators. We’ll cover key principles, applications, and considerations for maximizing efficiency and performance, ensuring you have the knowledge to select and operate the right system for your needs. Learn about different types, common challenges, and best practices for maintenance.

What are Shell and Tube Evaporators?

A shell and tube evaporator is a heat exchange device used to evaporate liquids by boiling. It consists of a cylindrical shell containing a bundle of tubes. The liquid to be evaporated flows inside the tubes, while a heating medium (typically steam) flows through the shell, transferring heat to the liquid and causing it to boil. The vapor produced is then separated from the concentrated liquid. This process is crucial in many industries for concentrating liquids, purifying products, and removing solvents.

Types of Shell and Tube Evaporators

Several variations of shell and tube evaporators exist, each designed for specific applications. Key distinctions often include the flow arrangement (e.g., single-pass or multiple-pass), the type of heating medium used, and the overall design for specific process conditions. Common types include:

Falling Film Evaporators

In falling film evaporators, the liquid flows down the inside walls of the tubes as a thin film, maximizing heat transfer efficiency. This design is particularly effective for heat-sensitive materials, minimizing residence time and reducing the risk of thermal degradation.

Rising Film Evaporators

Rising film evaporators utilize upward flow of the liquid within the tubes, facilitating better mixing and higher boiling rates. They are well-suited for applications requiring high evaporation rates and handling of higher-viscosity liquids.

Forced Circulation Evaporators

Forced circulation evaporators use a pump to circulate the liquid through the tubes, enhancing heat transfer and preventing local boiling or fouling. This design is particularly useful for liquids with high viscosities or scaling tendencies.

Key Design Considerations for Shell and Tube Evaporators

The optimal design of a shell and tube evaporator hinges on several factors. Careful consideration of these parameters ensures efficient operation and meets specific process requirements:

Heat Transfer Area

The size of the heat transfer area directly impacts the evaporation capacity. A larger area allows for greater heat transfer, increasing the evaporation rate. Selecting the appropriate heat transfer area depends on the desired evaporation rate and the properties of the liquid being processed.

Tube Material

The choice of tube material depends on the compatibility with the liquid being processed, the operating temperature and pressure, and corrosion resistance. Common materials include stainless steel, titanium, and various alloys.

Heating Medium

Selecting the appropriate heating medium is critical. Steam is often used due to its availability and efficiency, but other options, such as hot oil or thermal fluids, may be more suitable for specific temperature ranges or process constraints.

Optimizing Shell and Tube Evaporator Performance

Maintaining optimal performance of your shell and tube evaporator requires proactive measures. Regular maintenance, monitoring, and cleaning are crucial for extending lifespan and maximizing efficiency. These practices help minimize downtime and prevent costly repairs.

Troubleshooting Common Issues in Shell and Tube Evaporators

Understanding common problems and their solutions is vital for efficient operation. Issues can range from scaling and fouling to leaks and poor heat transfer. Proactive maintenance and proper operation can mitigate these issues.

Choosing the Right Shell and Tube Evaporator

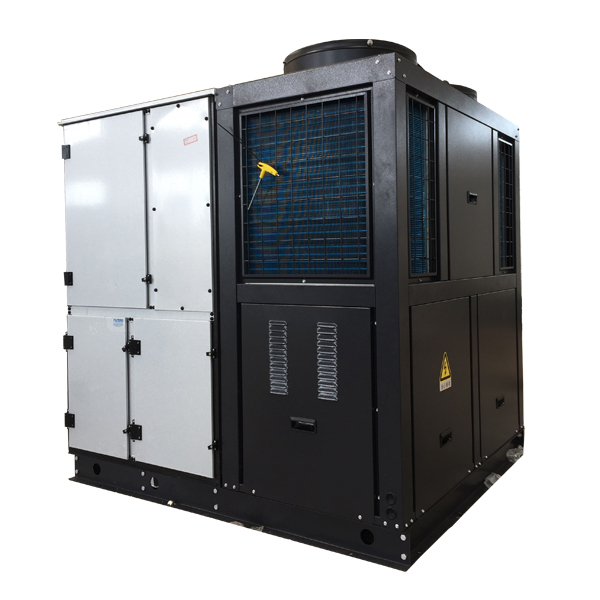

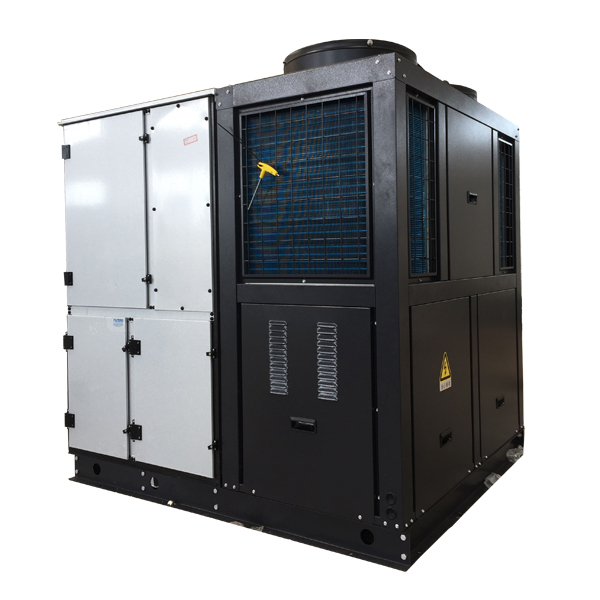

Selecting the appropriate shell and tube evaporator requires a thorough understanding of the process requirements and constraints. Factors such as the type and properties of the liquid to be evaporated, the desired evaporation rate, and the available utilities should all be considered. Consulting with experienced engineers or manufacturers, like Shanghai SHENGLIN M&E Technology Co.,Ltd, can ensure you choose the optimal system for your needs.

This article provides a comprehensive overview of shell and tube evaporators. However, specific design and operational requirements are highly dependent on individual applications. For detailed design considerations and customized solutions, contacting a specialist is recommended.

table { width: 700px; margin: 20px auto; border-collapse: collapse;}th, td { border: 1px solid #ddd; padding: 8px; text-align: left;}th { background-color: #f2f2f2;}