Understanding and Applying Double Tube Heat Exchangers

This comprehensive guide explores the design, application, and advantages of double tube heat exchangers. We’ll delve into their working principles, various configurations, and suitability for different industrial processes. Learn how to select the right double tube heat exchanger for your specific needs and discover real-world applications.

What is a Double Tube Heat Exchanger?

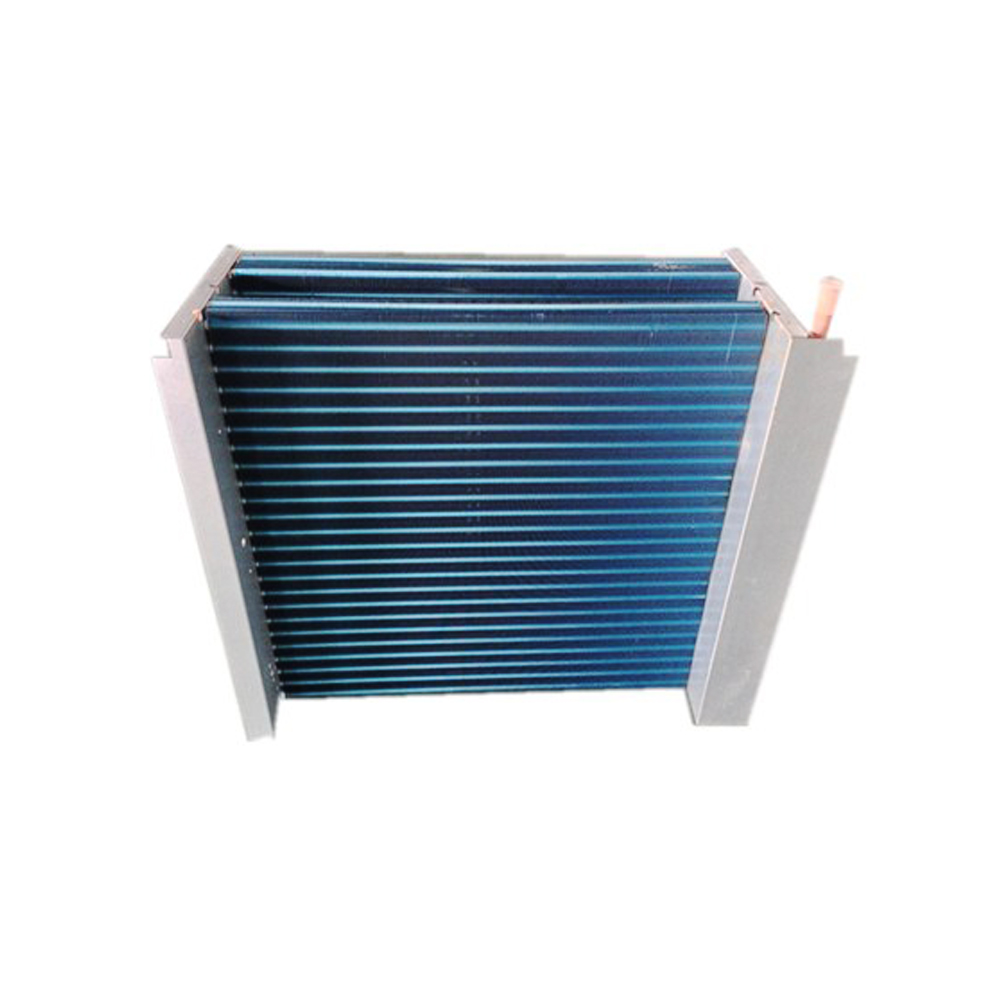

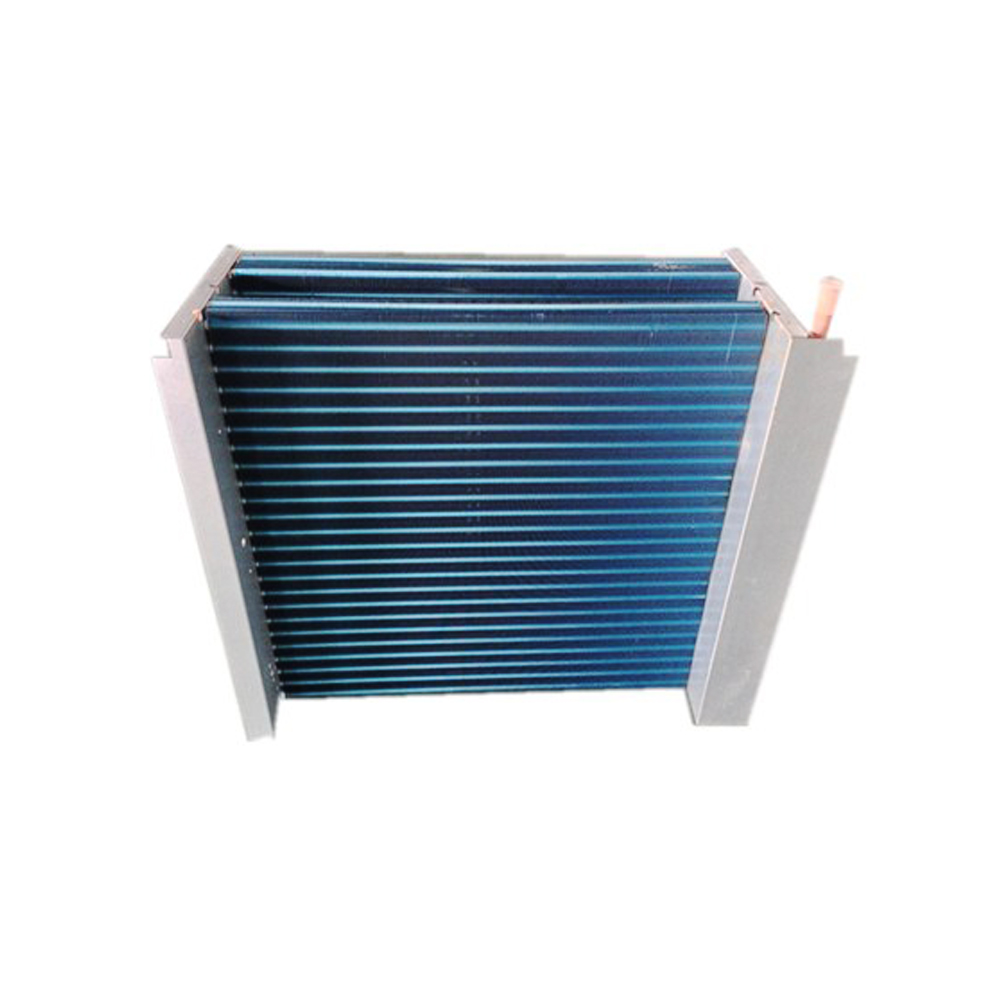

A double tube heat exchanger is a type of heat exchanger consisting of two concentric tubes. One fluid flows through the inner tube, while the other flows through the annular space between the inner and outer tubes. Heat transfer occurs through the tube wall, enabling efficient heat exchange between the two fluids. This simple yet effective design makes them versatile and widely used across various industries.

Types of Double Tube Heat Exchangers

Double tube heat exchangers come in several configurations, each suited to different applications and flow requirements:

Countercurrent Flow

In countercurrent flow, the two fluids flow in opposite directions. This configuration provides the highest possible temperature difference between the two fluids, resulting in the most efficient heat transfer. This is often the preferred design for applications requiring maximum heat recovery.

Cocurrent Flow

In cocurrent flow, both fluids flow in the same direction. While less efficient than countercurrent flow, cocurrent flow is simpler to design and maintain. It’s often used when a smaller temperature difference between the inlet and outlet fluids is acceptable.

U-Tube Configuration

A U-tube configuration involves bending the inner tube into a U-shape, allowing for a compact design and easier cleaning. This arrangement is especially useful when dealing with viscous fluids or those prone to fouling.

Advantages of Double Tube Heat Exchangers

Double tube heat exchangers offer several advantages:

- Simple Design and Construction: Their straightforward design leads to ease of manufacturing and maintenance.

- Compact Size: Relatively small footprint compared to other heat exchanger types.

- High Efficiency (especially in countercurrent flow): Capable of achieving high heat transfer rates.

- Versatility: Suitable for a wide range of applications and fluid types.

- Cost-Effective: Generally less expensive than more complex heat exchangers.

Applications of Double Tube Heat Exchangers

Double tube heat exchangers find applications in diverse industries, including:

- Chemical Processing

- Oil and Gas

- Pharmaceutical Manufacturing

- Food and Beverage Processing

- Power Generation

Selecting the Right Double Tube Heat Exchanger

Choosing the appropriate double tube heat exchanger depends on several factors, including:

- Fluid properties (viscosity, thermal conductivity, etc.)

- Required heat transfer rate

- Pressure and temperature constraints

- Space limitations

- Maintenance requirements

Case Study: Improving Efficiency in a Chemical Plant

A chemical plant utilized a series of inefficient shell and tube heat exchangers. By replacing them with a network of optimized double tube heat exchangers, the plant experienced a significant increase in energy efficiency and a reduction in operational costs. Specific data on this example can be found in relevant industry journals and case studies.

Conclusion

Double tube heat exchangers offer a simple yet highly effective solution for numerous heat transfer applications. Understanding their various configurations, advantages, and limitations is crucial for selecting the optimal design for a given process. For high-quality double tube heat exchangers and expert consultation, consider contacting Shanghai SHENGLIN M&E Technology Co.,Ltd. They offer a wide range of solutions to meet diverse industrial needs.