When you hear ‘sustainability’ in our line of work, the immediate thought often jumps to solar panels or wind turbines. But in the heavy industries—chemical plants, refineries, power gen—there’s a piece of kit that’s been quietly doing the heavy lifting for decades: the air cooled heat exchanger (ACHE). I’ve seen too many presentations where it’s glossed over as just a ‘fan and fin tube bundle,’ which misses the entire point. The real story isn’t in its basic function; it’s in how its inherent design philosophy cuts against the grain of resource-intensive cooling. It doesn’t need a massive body of water to operate. That single fact changes the sustainability calculus entirely, especially in water-scarce regions. But it’s not a magic bullet. I’ve been on sites where a poorly specified or maintained unit becomes an energy hog, completely undermining its environmental rationale. So, how do they genuinely enhance sustainability? It’s a mix of direct impact and subtle, systemic advantages that you only appreciate after seeing them in the field, through both successes and frustrating failures.

The Water Equation: More Than Just Conservation

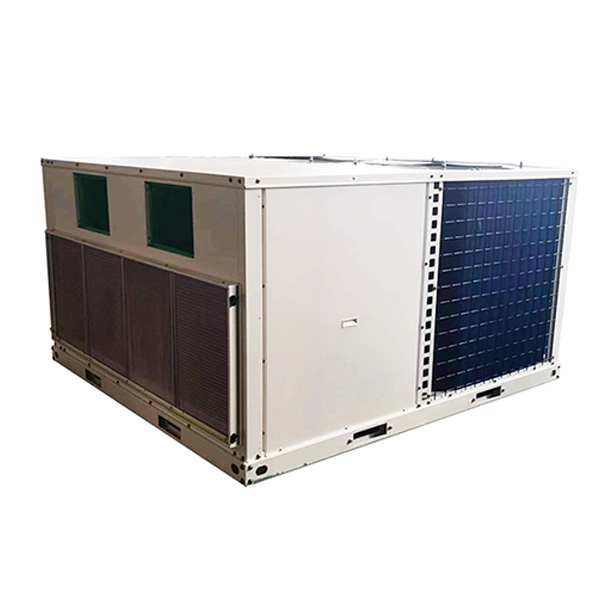

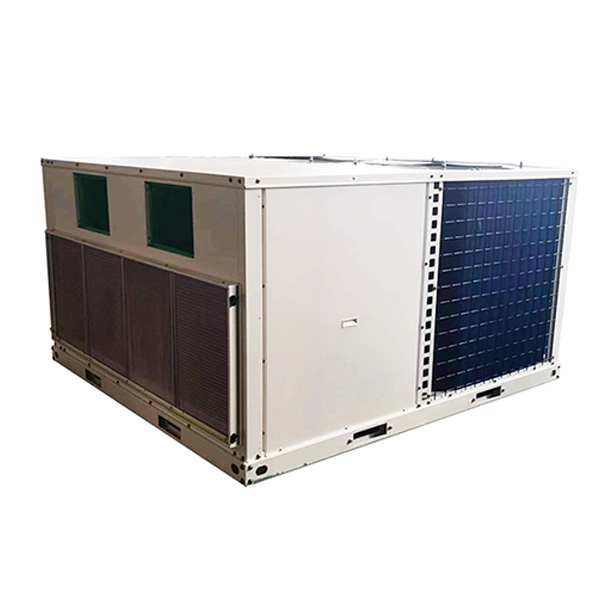

The most obvious starting point is water use. Traditional shell and tube heat exchangers rely on a continuous stream of cooling water, often from a river, lake, or massive cooling tower circuit. That means water withdrawal, treatment chemicals to prevent scaling and biofouling, and thermal discharge back to the source. An ACHE eliminates that entire loop. I remember a project in a drought-prone part of Texas for a gas processing plant. The client’s initial design called for a wet cooling system, but the permitting for water draw was a nightmare. We pivoted to a fin-fan cooler bank. The upfront cost was higher, but the operational freedom was immediate. No more negotiating water rights, no monitoring discharge temperature limits. The sustainability win here is absolute: it reduces the industrial footprint on local hydrology to nearly zero. For a manufacturer like Shanghai SHENGLIN M&E Technology Co.,Ltd, whose portfolio at https://www.shenglincoolers.com is built around these technologies, this is the core value proposition they engineer for—providing industrial cooling that sidesteps the water crisis altogether.

However, the ‘zero water’ claim needs a slight qualifier. You might have a small water wash system for cleaning the fin tubes if the air is particularly dirty, but that’s intermittent and a tiny fraction of what a cooling tower consumes. The real operational nuance is dealing with dry operation. When you remove the huge thermal mass of water, you’re left with air’s relatively poor heat capacity. This forces a different kind of design thinking—maximizing surface area with fins, optimizing airflow. It’s a trade-off that pushes material and fan energy efficiency to the forefront, which leads to the next, less obvious sustainability layer.

Energy and the Fan Dilemma

This is where the conversation gets gritty. Critics rightly point out that running large fans consumes significant electricity. I’ve walked past units where the fan noise is deafening, a sure sign of an inefficient system or one working too hard because of fouled tubes. The sustainability link is in the details of how you manage that energy input. Early in my career, we spec’d standard fixed-speed fans everywhere. Simple, robust. But then you’re at the mercy of ambient air temperature. On a cool morning, you’re overcooling and wasting fan power; on a hot afternoon, the process might trip because you can’t push more air. That’s not sustainable operation.

The shift to variable frequency drives (VFDs) on fan motors was a game-changer. Now, the fan speed modulates based on process outlet temperature or ambient conditions. The power draw of a fan is proportional to the cube of its speed. Reduce speed by 20%, and you nearly halve the energy use. I’ve seen retrofit projects where adding VFDs paid back in under two years purely on electricity savings. This is a practical, operational sustainability gain that turns the ACHE from a passive component into an actively optimized one. Manufacturers have caught on, designing lighter, more aerodynamic fan blades and more efficient gearboxes to squeeze out every percentage point of efficiency.

There’s also the indirect energy saving that’s often overlooked: no water pumping. A large cooling water system needs massive pumps to circulate thousands of gallons per minute. That’s a constant, huge electrical load that simply doesn’t exist with an air-cooled system. When you do the full plant utility balance, the net energy picture for an ACHE can be surprisingly favorable, especially in regions with moderate climates.

Material Longevity and Lifecycle Thinking

Sustainability isn’t just about operational inputs; it’s about the lifecycle of the hardware. A well-built ACHE is a brutalist piece of infrastructure. The core bundle—finned tubes in a carbon steel frame—can last 25-30 years with basic care. I’ve inspected units from the 80s that are still in service because the environment inside the tubes (the process side) is controlled, and the external fins, while susceptible to corrosion, are often made from aluminized steel or other protective coatings. This longevity avoids the frequent replacement cycles and associated manufacturing emissions of less durable equipment.

The failure modes are instructive. Tube leaks happen, usually at the fin-to-tube bond or where tubes roll into the header box. Repair is localized—you plug a tube or replace a section. Contrast that with a shell-and-tube exchanger where a major leak might mean pulling the entire bundle, a massive undertaking. The repairability extends the asset’s life significantly. We once had a bundle damaged by a crane swing on a site. Instead of scrapping it, the team from the fabricator, like what you’d expect from an experienced firm such as SHENGLIN, proposed cutting out the damaged bay and welding in a new module. The unit was back online in weeks, not months. That’s sustainable asset management.

However, material choice is critical. In coastal areas, salt spray can eat through carbon steel frames. I’ve seen projects where specifying hot-dip galvanizing from the start added 15% to the cost but doubled the expected service life. That upfront investment is a direct sustainability decision, reducing long-term waste and resource use for rebuilds.

System Integration and Waste Heat Recovery

Here’s a more advanced angle: using ACHEs not just as an endpoint for rejecting heat, but as a controllable element in a waste heat recovery scheme. It sounds counterintuitive—why would you want to reject heat more efficiently? The key is temperature control. Let’s say you have a process stream with waste heat that’s too low-grade to run a steam turbine, but you could use it for pre-heating feedwater or building heat. If your only cooler is a crude, oversized ACHE, it dumps all that heat to the atmosphere before you can harness it.

Modern designs allow for more sophistication. By splitting the bundle into sections (often called bays) and controlling fans independently, you can precisely control the outlet temperature. You can cool the stream just enough to meet process needs, then divert the still-warm stream to a secondary recovery loop. I was involved in a pilot project at a cement plant where we did exactly this. We used a modulated ACHE to maintain the optimal temperature for a downstream organic Rankine cycle (ORC) unit that generated auxiliary power. The ACHE wasn’t the star of the show, but its precise controllability made the entire recovery loop viable. This transforms it from a sustainability tool by subtraction (saving water) to one by enablement (facilitating energy recovery).

This requires a higher level of system design thinking. It’s not just buying an off-the-shelf cooler; it’s integrating it with controls and other process units. When it works, the synergy significantly boosts the plant’s overall thermal efficiency.

The Pragmatic Challenges and Trade-offs

To write about this without mentioning the headaches would be dishonest. Air cooling isn’t always the right answer. The big one is ambient air temperature. On a 45°C (113°F) day in the Middle East, the cooling delta T shrinks dramatically. You need a much larger surface area, which means more material (more embodied carbon), more plot space, and bigger fans. Sometimes, a hybrid (wet/dry) system is the truly sustainable optimum, using a small evaporative section to chill the air inlet on the hottest days, drastically cutting the footprint. I’ve seen projects where insisting on a 100% dry system for ideological reasons led to an oversized, inefficient monster that was worse on a full lifecycle assessment than a smart hybrid design.

Another real-world issue is air-side fouling. In a dusty environment or near a fertilizer plant, fins clog fast. The airflow drops, performance tanks, and fan energy soars. You need an effective cleaning strategy—often automated on-line cleaning systems with rotating nozzles. If you neglect this, the sustainability benefits evaporate as the unit guzzles power to push air through a clogged matrix. It’s a maintenance culture problem as much as an engineering one.

So, do they enhance sustainability? Absolutely, but conditionally. They offer a robust path to decouple industrial cooling from water stress and offer deep energy savings through smart control. Their durability reduces lifecycle waste. But the enhancement isn’t automatic. It comes from thoughtful specification—right-sizing, material selection, fan control strategy—and committed operational maintenance. In the hands of a knowledgeable operator and backed by solid engineering from specialists, an air cooled heat exchanger becomes more than just a piece of pipework with fins; it’s a foundational component for building a resilient, resource-conscious industrial plant. That’s the practical reality, far removed from the glossy brochure talk.