This guide provides a comprehensive overview of dry coolers, helping you understand their different types, applications, and selection criteria. We'll explore key features, compare various models, and offer practical advice to ensure you choose the most efficient and effective dry cooler for your specific requirements. Learn how to optimize performance and minimize operational costs.

Understanding Dry Coolers: Types and Applications

What is a Dry Cooler?

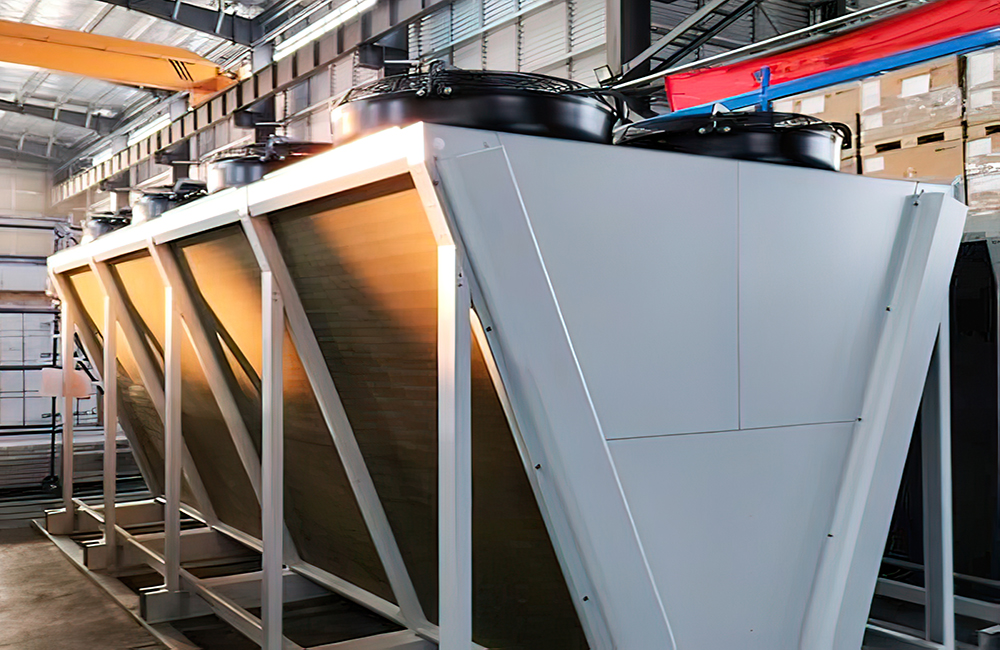

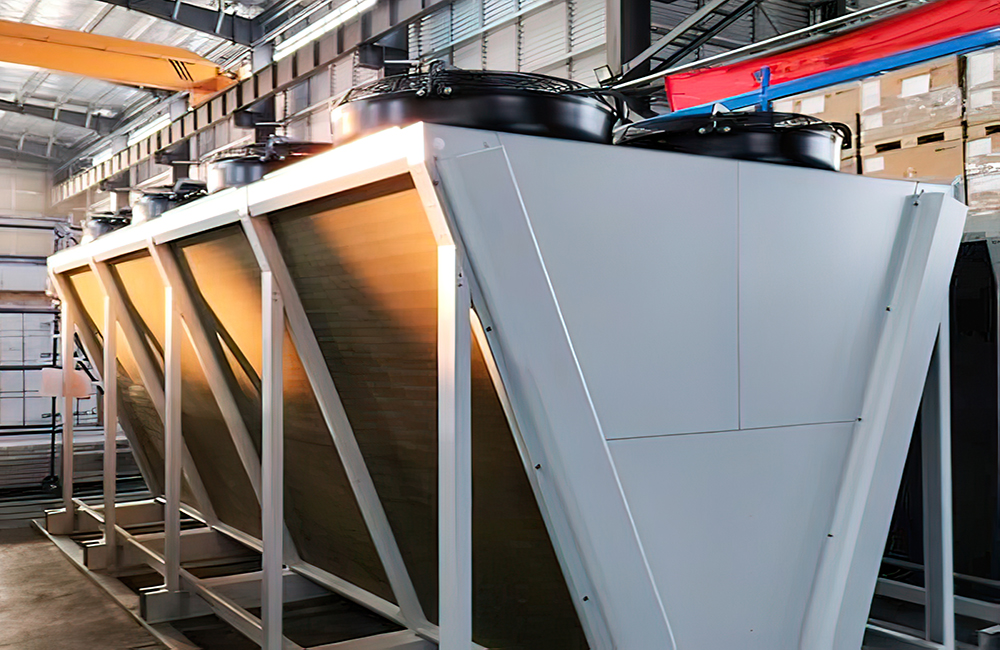

A dry cooler, also known as an air-cooled chiller, is a refrigeration system that uses air to dissipate heat. Unlike water-cooled chillers, they don't require a cooling tower, making them a space-saving and often more environmentally friendly option. They are particularly useful in applications where water conservation is critical or where water quality issues might impede performance. Dry coolers are commonly used in various industrial processes, HVAC systems, and data centers.

Types of Dry Coolers

Several types of dry coolers are available, each designed for specific applications and cooling capacities. These include:

· Air-cooled condensers: These are the most basic type and are suitable for smaller applications.

· Evaporative dry coolers: These combine air and evaporative cooling to achieve higher efficiency.

· Adiabatic dry coolers: These utilize water to improve heat transfer but consume less water than traditional water-cooled systems.

The choice depends heavily on factors such as ambient temperature, required cooling capacity, and available space.

Key Factors to Consider When Choosing a Dry Cooler

Cooling Capacity and Efficiency

The cooling capacity of a dry cooler is measured in kilowatts (kW) or tons of refrigeration (TR). It's crucial to choose a unit that meets your specific cooling needs. Efficiency, often measured by the Energy Efficiency Ratio (EER) or Coefficient of Performance (COP), is another critical factor. A higher EER/COP indicates better energy efficiency and lower operating costs. Consider the ambient temperature range and the expected load profile when evaluating efficiency.

Size and Footprint

The physical dimensions of the dry cooler are a crucial consideration, especially in applications with limited space. Carefully measure the available area to ensure the selected unit fits comfortably. Consider the airflow requirements and the space needed for maintenance access.

Maintenance and Operating Costs

While initial purchase price is important, consider long-term operational costs, including energy consumption and maintenance. Some dry coolers require more frequent filter cleaning or other maintenance tasks. Look for features that simplify maintenance and minimize downtime.

Comparing Different Brands and Models

There are numerous manufacturers of dry coolers, each offering a range of models with different specifications and features. Researching different brands and comparing their specifications is essential for making an informed decision. Consider factors such as warranty, customer support, and the manufacturer's reputation.

Finding the Right Dry Cooler for Your Application

To select the optimal dry cooler, carefully analyze your specific needs and constraints. Factors such as cooling capacity, ambient temperature, available space, budget, and maintenance requirements should all be considered. Consulting with a qualified HVAC professional can be highly beneficial in ensuring the correct selection.

For high-quality and reliable dry coolers, consider exploring options from Shanghai SHENGLIN M&E Technology Co.,Ltd. We offer a wide range of solutions to meet diverse cooling needs.

Remember to always refer to our specifications for the most accurate and up-to-date information.