When you hear air cooled condenser, the immediate thought for many in our field often jumps to water savings—which is correct, but it’s also a bit of a surface-level take. I’ve seen projects where that singular focus led to oversights in site-specific airflow dynamics or material selection, ironically compromising long-term efficiency. The real sustainability angle isn’t just about replacing water with air; it’s about how the system integrates into a facility’s entire energy and resource loop over a 15-20 year lifespan. Let’s unpack that.

Beyond the Obvious: Water is Just the Starting Point

Sure, the most direct benefit is eliminating cooling water make-up and blowdown. You’re not pulling from municipal or ground sources, and you’re not dealing with chemical treatment for scale or biological growth. I recall a food processing plant in a drought-prone region—switching from a cooling tower to an air cooled system cut their annual water draw by millions of gallons. But the sustainability story gets nuanced fast. If the fan motors are inefficient or the fin design collects debris, the energy penalty can offset those water gains. It’s a balancing act from day one.

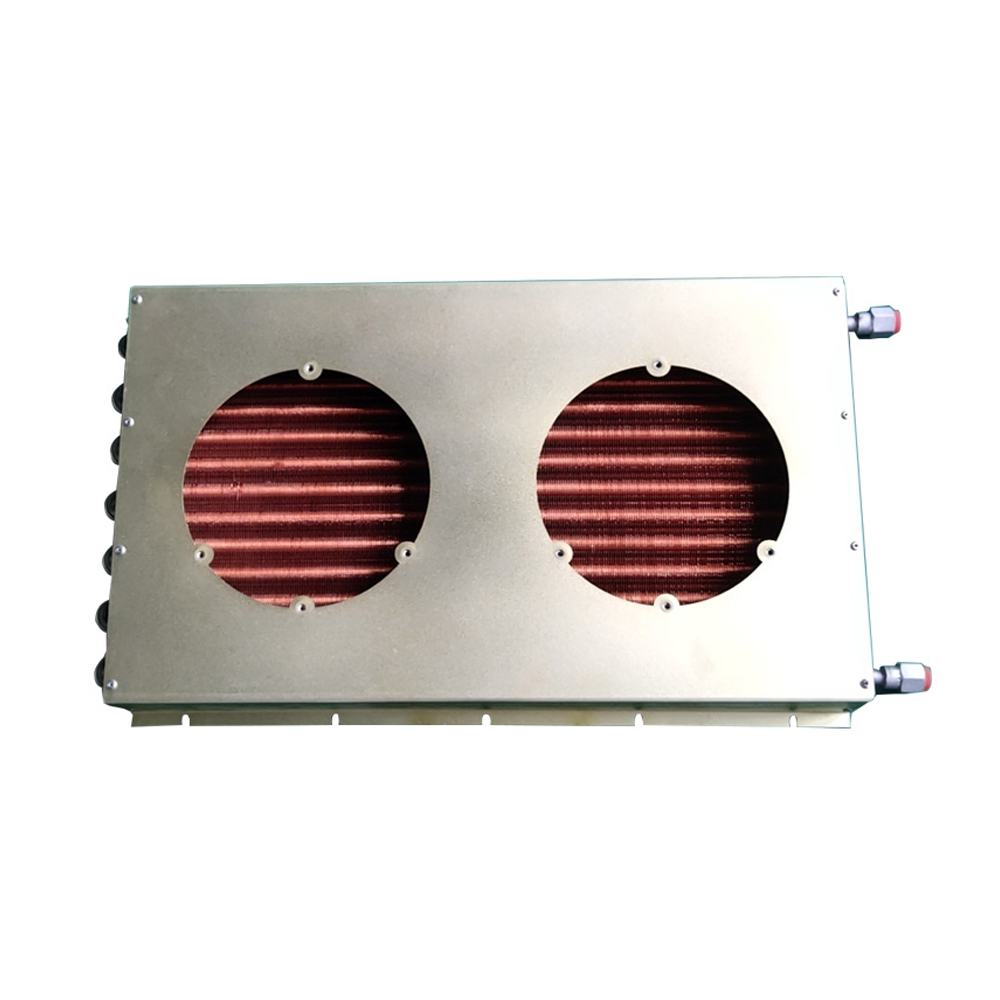

This is where the aire hoztua kondentsadorea design intent matters. A well-designed unit isn’t just a heat exchanger with fans bolted on. The coil circuitry, fin density, and fan staging should be tailored to the local ambient temperature profile and the specific refrigerant’s characteristics. I’ve worked with specs that copied a design from a cool, dry climate and applied it to a hot, humid coastal site. The result? Constant high-head pressure, compressors straining, and energy use that wiped out any environmental benefit. The lesson: sustainability is location-locked.

There’s also the material footprint. Heavier-gauge coils and corrosion-resistant coatings (like hot-dip galvanizing after fabrication) extend service life dramatically. I’ve torn down 20-year-old units from manufacturers who prioritized this, like SHENGLIN, and the structural integrity was still there. Contrast that with thinner, pre-coated coils that might show pitting in five years in an aggressive atmosphere. Sending a massive steel structure to scrap early is a huge sustainability loss, often overlooked in the initial CAPEX conversation. You can check their approach to build quality at https://www.shenglincoolers.com—it aligns with this long-view philosophy.

The Energy Equation: It’s Not Just About the Compressor

Conventional wisdom says air cooled condensers have a higher condensing temperature than water-cooled, so the compressor works harder, right? Generally true, but it’s an incomplete picture. Modern aire hoztua kondentsadorea designs with variable frequency drive (VFD) fans and ambient temperature-based head pressure control have closed that gap significantly. We implemented a system for a cold storage facility where the fans ramped down during cool night hours, maintaining a near-constant condensing pressure. The annual energy consumption came within 5% of a water-cooled tower with pumps and water treatment, without the water risk.

The hidden energy factor is parasitic load. A cooling tower has pumps, water treatment systems, and maybe heating for freeze protection. An air cooled system’s parasitic load is almost entirely the fan motors. When you spec high-efficiency EC or IE5 motors, the total site energy picture changes. I did an audit once and found the water treatment system’s dosing pumps and controls were drawing more continuous power than anyone had accounted for. Eliminating that whole subsystem is a direct energy and maintenance win.

Then there’s heat recovery potential. It’s trickier with air cooled systems because the heat is diffuse, but not impossible. I’ve seen setups where the condenser discharge air is ducted to adjacent spaces for wintertime make-up air heating, offsetting boiler load. It’s a niche application, but it points to system-level thinking. The sustainability gain isn’t just in the box; it’s in how the box connects to everything else.

Refrigerant Management and Leakage: A Critical Angle

This is a huge, often under-discussed point. Air cooled condensers, by eliminating the water loop, also eliminate one major source of refrigerant leakage: the evaporative condenser. No more water-induced corrosion on refrigerant tubes. The entire refrigerant circuit is contained within a sealed, air-cooled coil. From a lifecycle perspective, lower leak rates mean less refrigerant top-up, which is a direct environmental win given the global warming potential (GWP) of most working fluids.

I remember a chemical plant that had chronic leaks in their evaporative condenser bundles. The constant water exposure and treatment chemicals ate through the tube walls. Switching to an air cooled design stopped those leaks cold. Their annual refrigerant purchase dropped to nearly zero, just for occasional maintenance. When you calculate the CO2-equivalent emissions of manufactured refrigerant, that’s a massive sustainability contribution. The aire hoztua kondentsadorea becomes a containment strategy.

This also ties into end-of-life. Decommissioning an air cooled coil is straightforward: recover the refrigerant, cut the lines, and recycle the metal. There’s no contaminated water or sludge to dispose of. The recyclability of the aluminum fins and steel frame is very high. We’ve worked with scrap yards that give a premium for these clean, segregated materials. It’s a cleaner end-of-life cycle, which is a core tenet of sustainable design.

Real-World Trade-offs and Operational Realities

It’s not all upside. Footprint and noise are the classic trade-offs. An air cooled condenser needs a lot of air, which means space and clearances. I’ve had projects where space constraints forced us into a compromised layout, recirculating hot air and killing efficiency. Sustainability took a back seat to real estate. Sometimes, using induced-draft designs or installing vertical discharge units can mitigate this, but it adds complexity and cost.

Noise can be a community relations issue, which is a social sustainability factor. Early in my career, we installed a large battery of fans near a property line. The low-frequency hum led to complaints. We ended up adding acoustic barriers, which then affected airflow. It was a retrofit nightmare. Now, we model sound power levels during design and look at slower fan speeds with larger diameters. Companies that provide good acoustic data, like SHENGLIN (you can see their specs online), make this easier. It’s a detail, but getting it wrong can turn a green project into a local nuisance.

Another operational reality is fouling. Dust, pollen, lint—they all coat the fins. A dirty coil can increase condensing pressure by 20-30 psi, a massive efficiency hit. Sustainable operation requires a reliable cleaning regimen. I’m a fan of pressurized water cleaning, but it uses water, creating an ironic loop. Some sites use compressed air. The key is designing for easy access. I’ve seen coils packed so tightly into a frame that cleaning was impossible. That’s a design failure that undermines the unit’s entire sustainable lifecycle.

The Supply Chain and Manufacturing Lens

Sustainability isn’t just on-site; it’s also about how and where the unit is built. Localized manufacturing cuts down on transportation emissions. If a project is in Asia, sourcing a condenser from a regional specialist like Shanghai SHENGLIN M&E Technology Co.,Ltd, a known player in industrial cooling, makes more sense than shipping from across the globe. Their focus on industrial cooling technologies often means designs are robust for long-term use, which is sustainable in itself.

The manufacturing process matters too. Are coils mechanically expanded or brazed? Brazing uses less energy and material. Is the paint powder-coated, a process with minimal VOCs? These upstream choices contribute to the overall environmental footprint. When reviewing submittals, I now look for these details. A manufacturer’s commitment here often correlates with the in-service reliability of the aire hoztua kondentsadorea.

Finally, there’s the knowledge sustainability. A well-built, standard design from a reputable maker ensures spare parts are available for decades. This extends service life. I’ve battled with obsolete parts for custom units, leading to premature replacements. Standardization, paradoxically, supports sustainability by ensuring maintainability. It’s about creating systems that last, with a supply chain that supports that longevity.

So, enhancing sustainability with an air cooled condenser isn’t a checkbox. It’s a multi-variable optimization problem played out over decades. It’s choosing the right design for the location, prioritizing quality materials for longevity, integrating smart controls, managing the refrigerant lifecycle, and accepting the operational duties it brings. When all those align, the water savings are just the welcome bonus on a much deeper resource efficiency gain. The goal is a system that hums along efficiently for years, with minimal fuss and waste—that’s the real win.